16 awg to mm2

Request Quote Subscribe Login. As a general rule of thumb, for every 6 gauge decrease, the wire diameter doubles, and every 3 gauge decrease doubles the cross-sectional area.

The American Wire Gauge chart is based on the number of dies originally required to draw the copper down to the required dimensional size. It means the higher the AWG number is, the smaller the wire diameter is. Our Belden cables and the pairs in instrumentation cable are some of the electrical cables where the conductor size is expressed as an AWG figure. Return to FAQs. Cable size selection is based on 3 main factors: Current carrying capacity, Voltage regulation, Short circuit rating. Read more about the cable sizes and what determinate them There are two voltages that are widely used.

16 awg to mm2

So, for example, say you are a manufacturer of wire: you send it off to UL, they test it, and approve it, and provide a E-Number, which means the manufacturer holds the rights to that standard a bit like intellectual property. In the cable assembly business you learn your conversion tables off by heart much like your ABC, and times tables. Whether or not you like the idea of working in the Imperial System it is with us to stay, so to make things easy I have listed a simple conversion guide. The other caveat is the above table is based on stranded cable the vast majority of cables are made up of stranded conductors. Still confused? When I speak to people about what cables are best to use there are really only three things that matter. These are:. If you think this has been useful then please let us know. I hope that you can put this simple guide to good use. We are based in Silverstone, Northamptonshire which is central for motorway and dispatch routes in the UK. Facebook-f Twitter Linkedin-in. Nicab blog. Take a look at some of our other posts. Back to blog.

If you work in a sector involving the measurement of cables or wires, you may have come across the terms AWG and mm 2. White Papers.

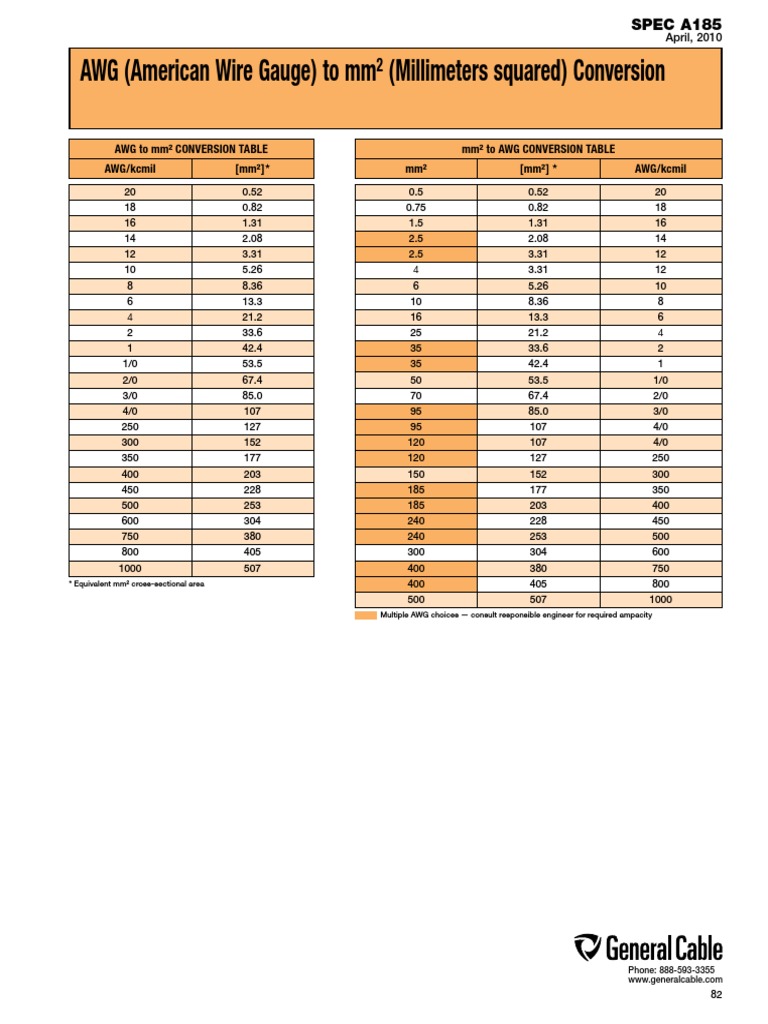

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. AWG is the US standard that defines the cross-sectional areas and diameters for solid, round electrical wire and is based on the number of dies required to draw down the raw copper to the appropriate size. Unfortunately, there is no easy way to convert AWG to an exact metric system measurement. Explore our tables below to see close approximations between AWG and metric sizes. The recommended numbers below are not always exact matches.

Request Quote Subscribe Login. As a general rule of thumb, for every 6 gauge decrease, the wire diameter doubles, and every 3 gauge decrease doubles the cross-sectional area. AWG is determined by first figuring out the radius of a wire squared, time pi. In fact, jacketing and insulation are not size determining factors of AWG. As a general rule of thumb, the higher the AWG number, the smaller or thinner the wire will be.

16 awg to mm2

In reality there is no exact correspondence between these two types of measurement since the specifications of both systems differ in terms of specification and resistance, however with the following application you can have a very good reference. It is an American standard for the size of conductors and cables. The AWG standard includes copper, aluminum, and other wire materials. Typical household copper wiring is AWG number 12 or

Toughbuilt tool bag

Facebook-f Twitter Linkedin-in. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. Still confused? You also have the option to opt-out of these cookies. This is why AWG wires are always slightly bigger in diameter than solid wire. The Cable Lab. Primary Automotive Wire. Ethernet Data Connectors. Return to FAQs. The recommended numbers below are not always exact matches. The higher the AWG number, the thinner the cable.

This converter has two text fields and control buttons that are used to execute different actions during the calculations. The first step of using the AWG to mm calculator is by selecting the gauge number which lies in the range of 0 to

Electrical Tape. Nicab blog. As a general rule of thumb, for every 6 gauge decrease, the wire diameter doubles, and every 3 gauge decrease doubles the cross-sectional area. If you still have questions, chat with us online or call us at Technical Information. Download the conversion table in PDF format here. Contact Nicab Ltd. Rectangular Connectors. If you need exact metric measurements, we recommend referencing data sheets and specifications for the products in question. Project Due Date. PVC Wire. Project Requirements To begin a list of products to include in your quote, click the Add to Quote button from any product page.

What exactly would you like to tell?