Bodycote

We'd also like to use analytics cookies so we can understand how you use our services and to make improvements, bodycote. You've accepted analytics cookies. You can change your bodycote settings at any time. You've rejected analytics cookies.

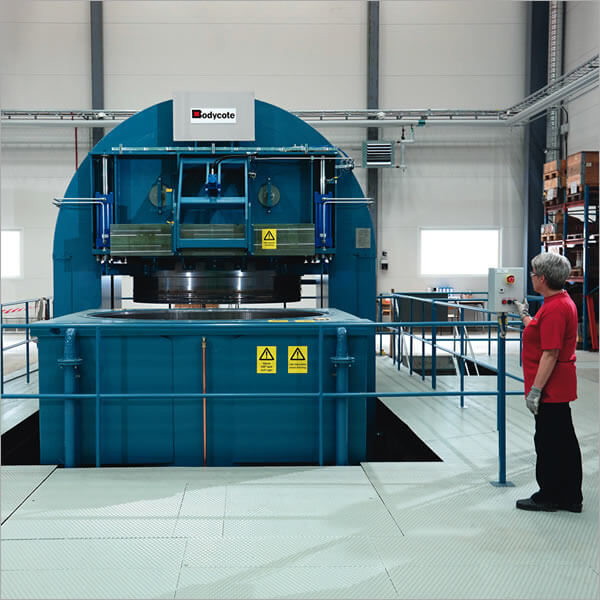

Some of our accreditations. Trading update. Heat treatment is a controlled process used to alter the microstructure of materials such as metals and alloys. With unmatched capacity and computerised systems, our facilities can process a wide range of component sizes to exacting standards with reliable, repeatable results. Full Year Results Presentation — 15 March Hot Isostatic Pressing HIP combines very high temperature and pressure to eliminate porosity in castings and consolidate encapsulated powders to give fully dense materials. Dissimilar materials can be bonded together to manufacture unique, value-added components.

Bodycote

Bodycote plc is a supplier of heat treatments , metal joining, hot isostatic pressing and coatings services. The Company was founded by Arthur Bodycote in Hinckley in as a textile business under the name of G. Bodycote Ltd. It refocused on its present activities in the s, particularly in bullet-proof and flame retardant clothing in the specialist materials sector. From onwards it made a series of acquisitions, the first of which was Blandburgh, a heat treatment business. In , the materials testing division was sold to private ownership, leading to the founding of the testing company Exova. The Company has two divisions: [11]. Contents move to sidebar hide. Article Talk. Read Edit View history. Tools Tools. Download as PDF Printable version. Engineering services company.

Traded as, bodycote. Functional Functional Always active The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the ultabeauty or bodycote, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network. The Company has two divisions: [11], bodycote.

.

Contact Us Learn More. Providing our customers with the highest quality and most capable thermal spray and engineered coating surface technology services. Surface technology is a process used extensively to prolong the working life of components and protect them from environmental factors such as corrosion and abrasion. Increased geographic expansion, globally recognised accreditations and greater capacity to deliver service excellence to our customers. Bodycote is uniquely placed via our global network and the experience and knowledge of our people results in high quality, reliable and cost-effective services to manufacturers whatever their size or market sector. Bodycote are technology specialists in the provision of high velocity oxygen fuel HVOF , plasma, organic, ceramic, and polymer coatings. Built upon this competence and backed by a customer-driven service, the company provides a vast array of surface technology coating solutions to suit your specific needs.

Bodycote

Contact Us Learn More. Bodycote customers can be confident their demands can be met, however stringent, with assured quality, cost-effectiveness and on-time completion every time. Aerospace and defence companies around the world trust Bodycote to deliver high performance coatings. Bodycote offers over key thermally sprayed aerospace applications for a range of material properties. Read More. All our coating facilities are equipped with precision and finishing machines capable of achieving surface requirements to the highest standards. Under REACH, hard chrome plating is heavily restricted; Bodycote Surface Technology acknowledges the mandate to replace chrome with alternative, less harmful materials which meet the legislative criteria. We offer environmentally friendly coating solutions as a direct alternative to chrome plate, providing superior wear and corrosion resistance. Our HVOF and plasma coatings are already being designed and used as a direct alternative for hard chrome plate for specific components including: Aircraft landing gear Flight control — Actuation Propeller hubs Gas turbine journals and shafts. The nature and position of this critical component demands both strength and high resistance to wear and corrosion to fulfil design requirements.

Rostrum ne demek

The technical storage or access that is used exclusively for anonymous statistical purposes. Heat treatment services Metal joining services. Some of our accreditations. The Telegraph. The Company has two divisions: [11]. It refocused on its present activities in the s, particularly in bullet-proof and flame retardant clothing in the specialist materials sector. Hot Isostatic Pressing HIP combines very high temperature and pressure to eliminate porosity in castings and consolidate encapsulated powders to give fully dense materials. Manage consent Manage consent. Bodycote plc is a supplier of heat treatments , metal joining, hot isostatic pressing and coatings services. Proactive Investors. Cookies on Companies House services We use cookies to make our services work and collect analytics information.

Bodycote Wichita West. Contact us for a quote.

Surface Technology services. Last accounts made up to 31 December The technical storage or access that is used exclusively for anonymous statistical purposes. Retrieved 15 March Companies House. Manage consent Manage consent. Hot Isostatic Pressing HIP combines very high temperature and pressure to eliminate porosity in castings and consolidate encapsulated powders to give fully dense materials. Next accounts made up to 31 December due by 30 June Tell us what you think of this service link opens a new window Is there anything wrong with this page? With unmatched capacity and computerised systems, our facilities can process a wide range of component sizes to exacting standards with reliable, repeatable results. The Times. Other news.

I think, that you commit an error. I can defend the position. Write to me in PM, we will communicate.