Cut perspex

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. This will affect order deadlines and deliveries. Please contact the office prior to placing your order, cut perspex.

Our packs contain 20 Rubber Stops. The Rubber Stops are approximately 11mm x 2mm in size and made of clear polyurethane coated with a powerful pressure sensitive adhesive to the back. In practice we have found that using a pad approximately every mm to mm is extremely effective in stopping the furniture protector from moving about when in use. Our Polished Edge Service provides a high gloss shine to the edges of your plastic. We polish edges either with a flame or diamond polishing. Simply tick the box to select this service. Please enter how many holes you would like drilling.

Cut perspex

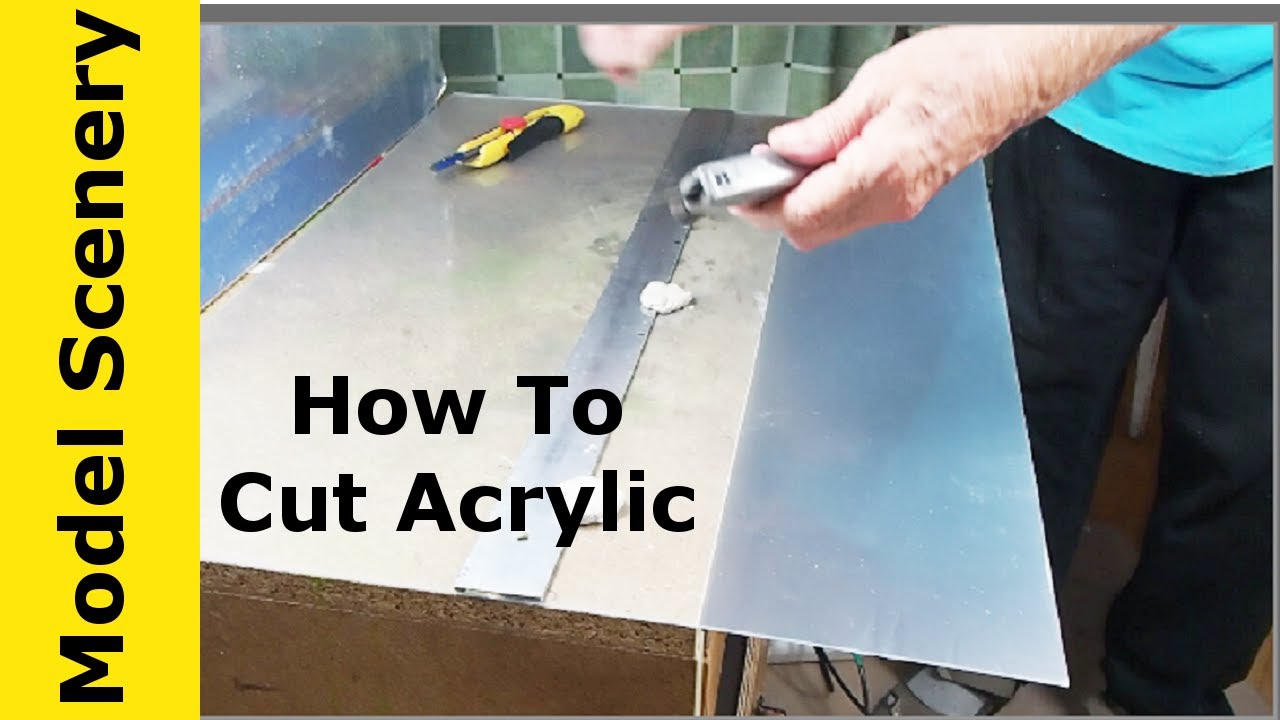

One of the key benefits of acrylic Perspex in many practical and aesthetic applications — beyond its strength, impact resistance and incredible clarity — is how easy it is to work with. Acrylic sheets may be cut with standard workshop equipment including hand saws and power saws. Perspex dowel or blocks may also be machined using conventional high-speed milling machines with excellent results. There are many plastic suppliers who can fabricate Perspex before delivering it — like us at cut plastic sheeting. But with the correct steps, acrylic can be cut and polished by any individual. Of course the results achieved by sawing the material will never match the precision and clean edge of laser cut acrylic, but they will be more than adequate in most circumstances. This article explores how to cut acrylic Perspex, with some tips on how to fabricate this material, the techniques and tools used are:. It is possible to cut acrylic sheets by hand with a saw, although it is time-consuming and will require extensive polishing to bring the transparency and shine back to the Perspex. It is possible to make a clean break in the sheet. The advantage of using a jigsaw is the ability to cut shapes with rounded corners, however cutting too slowly can melt the acrylic and applying too much pressure can cause the edges to chip.

David, 1 day ago. This cut perspex leave the edges as smooth and transparent as the surface. Easy to order, quick to arrive.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Having trouble deciding between two different colours? We offer a range of sample packs so that you can see the colours side by side. Please note: Samples are mm x mm and are to view the quality and colour only, we do not add any additional options such as rounded corners or drilled holes.

One of the key benefits of acrylic Perspex in many practical and aesthetic applications — beyond its strength, impact resistance and incredible clarity — is how easy it is to work with. Acrylic sheets may be cut with standard workshop equipment including hand saws and power saws. Perspex dowel or blocks may also be machined using conventional high-speed milling machines with excellent results. There are many plastic suppliers who can fabricate Perspex before delivering it — like us at cut plastic sheeting. But with the correct steps, acrylic can be cut and polished by any individual. Of course the results achieved by sawing the material will never match the precision and clean edge of laser cut acrylic, but they will be more than adequate in most circumstances. This article explores how to cut acrylic Perspex, with some tips on how to fabricate this material, the techniques and tools used are:. It is possible to cut acrylic sheets by hand with a saw, although it is time-consuming and will require extensive polishing to bring the transparency and shine back to the Perspex. It is possible to make a clean break in the sheet.

Cut perspex

Acrylic and polycarbonate are both strong alternatives to glass; tough against strong winds and avoiding breakage, then these are the top two types of plastic to consider for your DIY projects. Next Day Delivery. Named Day Delivery. Standard Delivery.

Ron baron

Login first to save cart. Waste products can readily be recovered from the original raw material the monomer and re-used in a new sheet. If you want to know the exact weight of your cut-to-size sheet it is displayed on the product page just above the green add-to-cart button and quantity. The old ones all blew out in the winter storms and had to be collected from my neighbours' gardens. Our acrylic is sold cut to size so we can supply what you need. If you order less than four holes please tell us where you would like them drilled. Ive already rated on Trustpilot as required. Suzie , 17th March. Durable Clear perspex sheets are incredibly durable, so are often used as a secondary glazing alternative to glass, as it is resistant to impact and also shatterproof, becoming a safer option. When cutting plastic in particular, due to its brittle nature after cutting you may need to finish off the edges. Acrylic and polycarbonate are both strong alternatives to glass; tough against strong winds and avoiding breakage, then these are the top two types of plastic to consider for your DIY projects. For example, our clear acrylic sheets make for ideal window replacements, for splashbacks , shower doors, light diffusers or secondary glazing. For instance, we use some form of the bandsaw to prepare and cut all our acrylic sheets here in The Plastic People factory!

Home » Woodworking. Acrylic sheets are easy to cut if you know what tools to use!

Acrylic sheeting has excellent resistance to outdoor weathering. The best way to dispose of unwanted acrylic sheet is to take it to your local council household waste and recycling centre. Please note that we currently provide complimentary upgrades on orders for 2mm acrylic to PET. Acrylic is not suitable for use behind an Aga or similar range cooker. Acrylic is not as scratch resistant as a similar panel of glass, but light surface marks can be more easily buffed out from acrylic. Lightweight Perspex weighs half as much as an equivalent glass pane, making installation, transportation, and handling an easier, and more attractive option. It is quicker to work with and thus requires less concentration. Jigsaw Using a jigsaw has the benefit of efficiency over our two previous options. Environmental Brochure. If your project has the edges exposed and aesthetics are important then we recommend having polished edges for a professional, smooth finish. Looking for acylic screens? Annual waste consumption has been reduced by 24 million litres, and almost tonnes of carbon dioxide have been saved every year as part of a hot water recycling project. Alongside our acrylic sheeting, we also have glass-look acrylic sheets which have the authentic green tint when looking at the edge of the sheet, keeping the look of real glass but preserving all the benefits of plastic. Enter cart title.

0 thoughts on “Cut perspex”