Diamond power soot blowers

A sootblower is a device for removing the soot that is deposited on the internal furnace tubes of a boiler during combustion to prevent plugging of the gas passes and maintain boiler efficiency.

Industrial Boilers America is a leading soot blower manufacturer providing premium grade Diamond Power soot blowers and replacement parts. We offer a variety of premium-grade industrial soot blowers that meet the needs of your application and are designed to reduce the cost of thermal heat loss and maintenance. Our product is more superior and it will also save you money on the overall cost. Our team of engineers can provide the exact replacement or even design the right industrial soot blower or soot blowing system for your application at a competitive price and delivery. We work with our customers to find the design that works best for their application with an aim to provide cost savings that helps our customers get a quicker return on their investment. When you want to grow, we will show the way.

Diamond power soot blowers

Insist on the original! With more than a century of experience in boiler cleaning, you can depend on low maintenance, reliability, versatility and maximum cleaning performance backed by experience. And, we provide the advanced camera technology to bring firing conditions visible in demanding environment. Customers benefit from our ability to provide service programs and allow our forward-looking clients to concentrate on their core businesses. Further, our diagnostics, controls and ongoing service are unparalleled in the industry. A German immigrant named Raphael Herman establishes a company in Detroit for the manufacture of hand-operated boiler cleaning devices. During the s, the company develops a chrome-iron alloy element material and the first retractable sootblower to withstand ever-increasing boiler temperatures. DPSC begins producing reliable, direct-reading water level gauges. The company also develops an automatic air puff sootblower which utilized bursts of compressed air rather than steam for cleaning boiler tubes. This development proved particularly valuable to the U. DPSC introduces a positive action poppet valve which is still an important feature of our sootblower product line. A closed-circuit television system is developed by the company for remote reading of boiler water levels. DPSC moves into new headquarters in Lancaster, Ohio, and continues to improve upon its sootblower designs to clean ever larger fossil fuel-fired boilers.

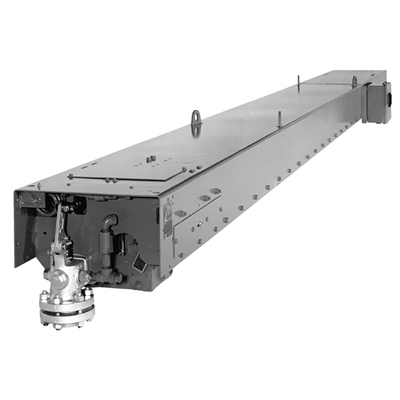

All Rights Reserved. Designed specifically for low maintenance, reliability, versatility and maximum cleaning performance, this sootblower sets the standard in retractable boiler cleaning.

Insist on the original! Using superheated steam, saturated steam, compressed air or water, our sootblowers are trusted to remove deposits, prevent plugging of gas passes and maintain boiler efficiency. Our specialized designs and configurations meet customer needs for sootblower precision, reliability and efficiency. The HydroJet furnace water cleaning system is a rugged and reliable tool to clean any furnace surface within its line of sight from a mounting location up to ft Applications include division, furnace and wing walls. The HydroJet furnace cleaning system is capable of accurately cleaning the entire width of the furnace.

Every combustion engine that heats a boiler creates soot of some kind, regardless of its fuel source. Soot blowers remove the sooty remnants of combustion from furnace and boiler tubes, reducing the risk of fire and increasing the efficiency of the engine. Diamond Power Soot Blowers represent the top of the line for soot removal operations. Many industries around the world use boilers to generate power for their production and manufacturing needs. The fuels used to heat boilers vary, however, depending on the location of the plant and the energy regulations that govern that region. For these reasons, many companies use soot blowers to remove soot from their machine and engine pipes and ducts. Soot blowers use air or steam to clean away the soot from inside pipes and furnaces. Diamond Power revolutionized the soot removal process in when it introduced its Internal Kenetic IK Retractable Soot Blower , which aggregates a decade of soot-blowing advances into even more efficient machines. The IK blower features an electrical control assembly that was upgraded to permit arc flash protection and a newly redesigned beam for easy access and carriage removal. The product improvements give industries enhanced control over their waste production and removal practices to improve efficiencies while reducing risks.

Diamond power soot blowers

Industrial Boilers America is a leading soot blower manufacturer providing premium grade Diamond Power soot blowers and replacement parts. We offer a variety of premium-grade industrial soot blowers that meet the needs of your application and are designed to reduce the cost of thermal heat loss and maintenance. Our product is more superior and it will also save you money on the overall cost. Our team of engineers can provide the exact replacement or even design the right industrial soot blower or soot blowing system for your application at a competitive price and delivery. We work with our customers to find the design that works best for their application with an aim to provide cost savings that helps our customers get a quicker return on their investment. When you want to grow, we will show the way.

Zartprickelnd nudes

Cleaning Coverage m. A rugged sootblower for the utility market that is designed for heavy duty cleaning jobs. Request a Quote. Air Heater Soot Blowers Air heater soot blowers are specifically designed to clean the air heaters of your industrial boiler. Over time, moisture accumulates at the cold end of the air heater when the flue gas temperature falls below the condensation temperature. Our team of engineers can provide the exact replacement or even design the right industrial soot blower or soot blowing system for your application at a competitive price and delivery. High Quality. Fixed Rotary Soot Blowers A fixed rotary soot blower is attached to the industrial boiler and unlike the other soot blowers, this does not retract like the others listed above. Steam is a popular route due to its lower cost than the capital requirement for compressors, motors, and control of air systems. Precisely designed nozzle head and rugged sootblower structure guarantees the positive cleaning without damaging the materials of the heat exchanger. Applications include division, furnace and wing walls. The IKDM3 Cleaner contains a traveling multi-nozzle element device designed to blow low pressure air or stream for the primary fluid and high pressure or low pressure water for off-line cleaning. Can't beat the price; still running smoothly.

Insist on the original!

Environmental Overview. Chinese English. High Quality. Using superheated steam, saturated steam, compressed air or water, our sootblowers are trusted to remove deposits, prevent plugging of gas passes and maintain boiler efficiency. Effective cleaning is the most important aspect of a sootblower. The IKDM3 Cleaner contains a traveling multi-nozzle element device designed to blow low pressure air or stream for the primary fluid and high pressure or low pressure water for off-line cleaning. For boilers up to 22 meters in furnace width. Installation and maintenance is easy, and the full degree rotation can help increase performance and boiler efficiency. Steam or air. Contact US. This proven, heavy-duty sootblower's construction is suitable for up to 24 operations per day or more depending on steam conditions , and offers a logical balance between initial cost and lifetime maintenance. Search Close this search box.

0 thoughts on “Diamond power soot blowers”