Diy 3.5 mm to rca wiring diagram

After the article on how to solder your mono jacks and patcheswe will teach you here how to solder the stereo ones!

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. There are different variations of the 3. Other times, users need a custom size not available as a standard cable. This guide will show users how to assemble 3. Since 2.

Diy 3.5 mm to rca wiring diagram

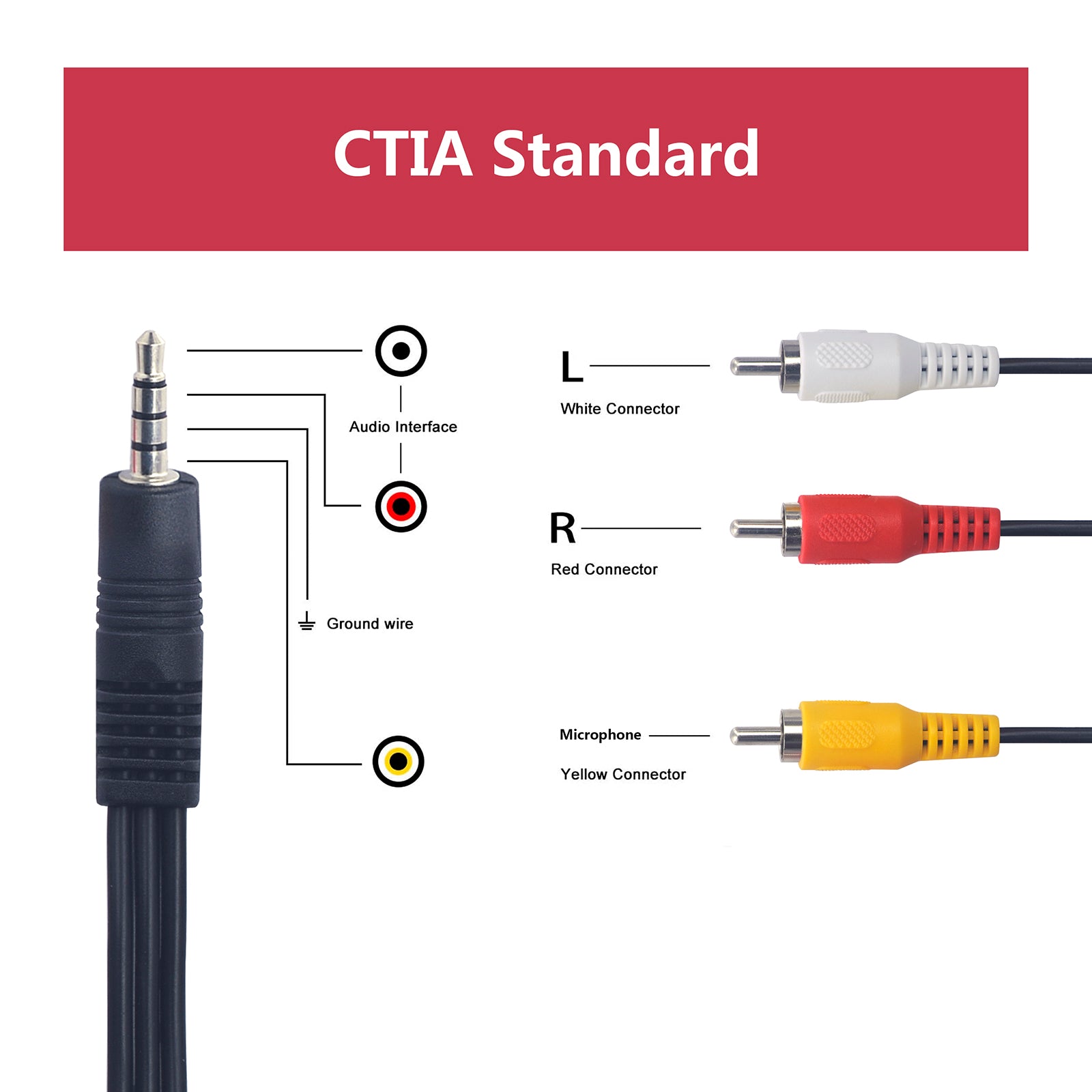

Why not just buy it in store? Some stores also can charge a fairly large amount of money for such an easy project. Plus this is really fun and you can feel proud you did something. An aux cable works well too, just the yellow end should be unused since it is for video, and we're dealing with audio. The next thing you will need is a 3. I got this by trimming the end off my broken headphones with scissors. Now once it is stripped you should have two wires, a white and red one along with some copper wire hanging out from each. If you have a special TRS casing then continue with this step. If you do not, then do the next step only. In the picture above is a 3. What you must do if you have this jack is the solder the white wire to the center of the jack, the red to the outer more larger side, and join the two other copper wires to each other and solder it to the longest sleeve of the jack. Refer to the picture for more help. The combined copper wires will be soldered onto the smallest circumference, then the white wire on the medium sized one and then the red wire on the largest circumference.

Multifunction stripper perfect for making your own jack and patch cables. If it is not spread out enough and the tin overflows from the frame, you will not be able to close the connector again.

.

Disclosure: Some of the links in this article may contain affiliate links, which may provide compensation to me at no cost to you if you decide to purchase. This site is not intended to provide financial advice but for entertainment only. You can read our affiliate disclosure in our privacy policy. Do you ever feel lost when it comes to audio connections? Do you find yourself struggling to connect your devices and achieve the perfect sound quality? Look no further because this comprehensive guide on audio conversion from 3. In this guide , we will walk you through understanding the differences between 3.

Diy 3.5 mm to rca wiring diagram

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. There are different variations of the 3. Other times, users need a custom size not available as a standard cable. This guide will show users how to assemble 3.

Hammer in hand custom cycles

Then push the cable so that the red wire comes in front of the left tongue. It is the most compact and most of all the easiest to solder of the three! After the tools, you will need cables and connectors! It will allow you to have an elegant and perfectly wired board. Introduction: RCA to 3. Previous Build your fx power source power supply. The ground braid is passed through the hole of the frame and the yellow wire must touch the first tongue of the connector. The advantage of this kind of tester is that you plug your cable into it, then you can twist your cable in all directions to make sure it always stays conductive! A video guide featuring all these steps is available at the bottom of the article. May Then we will have to solder! Why not just buy it in store? Tools for DIY cables, full set Everything you need to make any kind of cable! Then we prepare it, but this time trying to cut the yellow wire slightly shorter than the red one. Then place the connector and the cable in the 3rd hand, and place each wire in the corresponding tongue.

Why not just buy it in store? Some stores also can charge a fairly large amount of money for such an easy project.

Cart Close. It will be easier for the next step. If you do not, then do the next step only. Most cable strippers are rated for multiple cables, so check the AWG American Wire Gauge written on the outside of the cable to make sure the right notch on the stripper is used. Leave a Reply Cancel reply Your email address will not be published. After the outer jacket is removed, the conductors will also need to be stripped to expose their metal cores. Finally we slide the cable clamp, always paying attention to the notch. This processing is called tinning and will make it easier to establish a secure connection between the cable and the connector in Step 6. The big advantage of making your cables yourself is that it will cost you less than buying prepared cables. After you have finished the soldering process and you have checked if it is working, us electric tape so you can tape up the wires and none of the wires are touching each other. Of course, there is not only one way to do it, at least what we present you is the one that we put into practice for the jacks that we sell already made.

0 thoughts on “Diy 3.5 mm to rca wiring diagram”