Drilling lintel

Follow along with the video below to see how to install our site as a web app on your home screen. Note: This feature may not be available in drilling lintel browsers. If you need to find a tradesperson to get your job done, please try our local search below, drilling lintel, or if you are doing it yourself you can find suppliers local to you. Are you a trade or supplier?

Armstrong Cheshire June 25, Your tape measure has done its job and everything fits your window frames fine, but when you try to affix the fittings, you may come across some resistance. This is the lintel - a solid beam located above both windows and doors in buildings. How difficult this will be is dependent on what the lintel in your home is constructed from. Timber lintel beams were once common and quite easy to drill through but eventually fell out of fashion for their lack of durability and vulnerability when it comes to fire. Concrete and steel lintels are more common options now, but can be just as tricky to drill through. What is a lintel?

Drilling lintel

Follow along with the video below to see how to install our site as a web app on your home screen. Log in Register. Search titles only. Search Advanced search…. New Posts. Unread Posts. Posting Guidelines. Search forums. Log in. Install the app.

How to drill into a concrete lintel When drilling into a concrete lintelyou should start with the smallest drill bit for masonry you have in your set, drilling lintel. Are you a trade or supplier?

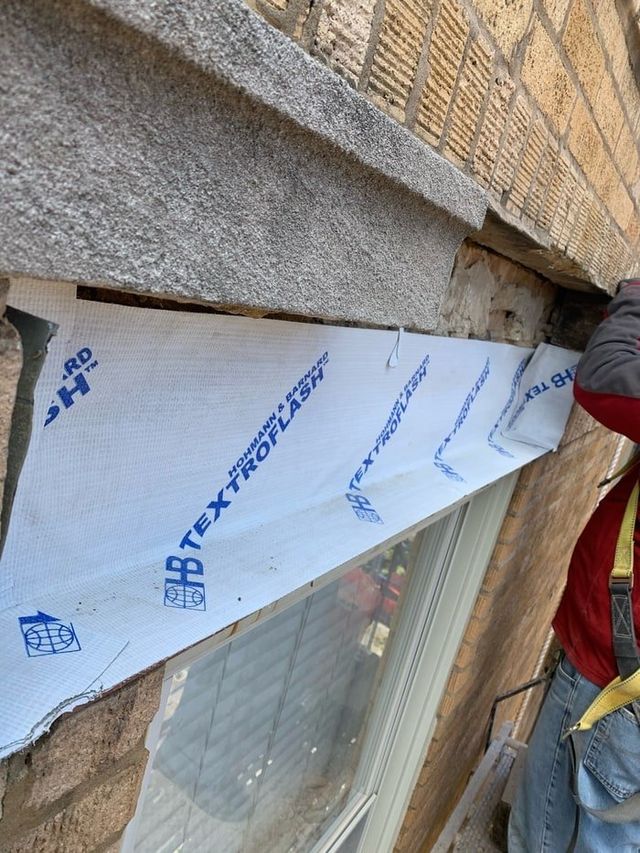

A DIY guide to drilling into lintels including fixing to lintels made of steel or concrete and how to avoid problems drilling and fixing into concrete or steel lintels. If you need to fix a blind or curtain rail into a window recess this will probably involve drilling. This can be a tricky job as both materials are tough. In this guide we will also show you a method of fixing that avoids the need for drilling into concrete or steel lintels. Don't want to do this job yourself?

There are occasions when you may consider drilling into a lintel. If this is the case, you may be wondering if this is OK, and also the best way to do it. In this article we will be looking at whether you can drill concrete lintel. As well as the different types of lintels and whether they can be drilled. Lintels are a structural beam found above openings, such as doors and windows. They can be made from several different materials. These include:. However, you may want too in some instances. For example, if you are fitting curtain rails or some blinds. This will mean you are fitting to the internal side of your lintel.

Drilling lintel

While putting up blinds or curtain rails you might have experienced some resistance. This resistance is caused by lintels which are a structural support built on windows and doors. While drilling into lintels can be a challenging task, with the right information you can easily accomplish it. In this article I will guide you about the different type of lintels you can come across and how you can drill through each of them. How to Drill into Lintels? Use a standard drill bit for drilling into a timber lintel. For stone, lintel uses a metal-bonded diamond drill bit. You can drill into the brick lintel, reinforced brick lintel, and reinforced cement concrete lintel using masonry bits until you hit a metal bar.

Quetzal tattoo

Thanks both, hopefully a new drill bit, cutting paste and more patience will see me through! Having a drill that is carbide-tipped may be more effective in puncturing a hole, as the hole will be cleaner and will easily make its way into the concrete compared to other drill bits. Ideally for the most secure fix any paint should removed back down to the plaster or similar covering if there is one and the timber fixed to this, but in most cases as long as the paint or similar is in good condition and fully bonded to the surface beneath it should be fine. NBT 7 Dec Building 6 7 8. I've drilled loads of holes in them, not even with a sharp bit always. It was stronger than plasterboard fixings or attaching a wood batton, which I don't think I'd like the look of. The cappit is glued up to the timber and the same procedure is used to hold the cappit in place for 24 hours. A masonry drill until you hit a rebar followed by decent HSS will probably work out. Thanks I appreciate it probably isn't an RSJ but its bloody hard. I've used this trick to attach to a 2. Once the damage is done, there is nothing that can fix it, which is why extreme caution should be practiced. I used an 18v Makita cordless but it was hard work. Joined 4 Dec Messages 1 Reaction score 1 Country. Thanks for any advice.

Handyman's World is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.

Likewise, if the paint or other covering is loose and flaking away then the adhesive you use will simply stick to the loose paint and therefore fail in no time. Log in or Sign up. They are most likely catnic type lintels and should drill fairly easy to be honest as long as you dont blunt your drill bits by going into masonry. Basically I'm just saying that you can't fit a SDS drill bit into a normal drill, or into a hammer action drill. More Help. I was using a plantinum drill bit hss from black and decker but seem to be making little headway. Or are they bad at all jobs. Find Us On The Web. I'm considering getting a better drill to fit the blinds, curtains and cabinets in my new place. I tried 3mm, 4mm and 6mm of the following: Dewalt Hex shank Cobalt - these are nice with a self centrer-ing tip and but blunted too fast Bosch Straight - 3mm one snapped but likely my fault, better than Dewalt but again didn't stay sharp long Milwaukee Thunderweb Straight - stayed sharp, I used the 3mm and 4mm and were very good and then moved onto - These are not branded as Thunderweb on the page but they are packaged as such Milwaukee Hex Shank Shockwave Impact only bought 6mm - Stayed very sharp - hex shank is really helpful even in a standard chunk also cheaper than Milwaukee Thunderweb straight 6mm Before this I was using the Bosch multi construction bits , these have worked great for me previously but nothing as hard as these lintels! They can make the procedure faster to complete and can be on the lookout for some dangerous signs that can be hard to see on your own, such as cracking and crumbling concrete. Use dry walling screws with a pilot hole 0. Armstrong Cheshire June 25, Catnic and box lintels are tinfoil by comparison.

0 thoughts on “Drilling lintel”