Electrical pull box sizing

Chapman Electric Supply, Inc. Determining the size of underground pull and junction boxes to meet NEC

Pull boxes are used along with conduit to simplify wiring installation , hence their name. They are made of sheet metal , cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive strain on the wire or insulation. Pull boxes allow long wiring runs to be installed in shorter intervals, and can be used for both straight and angled pulls. Although they have the same appearance as junction boxes, pull boxes do not have wiring connections inside. They are only access points for pulling and feeding conductors into a raceway system. Their use is mandatory in conduit runs where the number of bends between outlets exceeds the maximum number permitted by the NEC National Electric Code. Pull box sizing is based on the size and number of conductors, as well as the number of raceways and their diameter.

Electrical pull box sizing

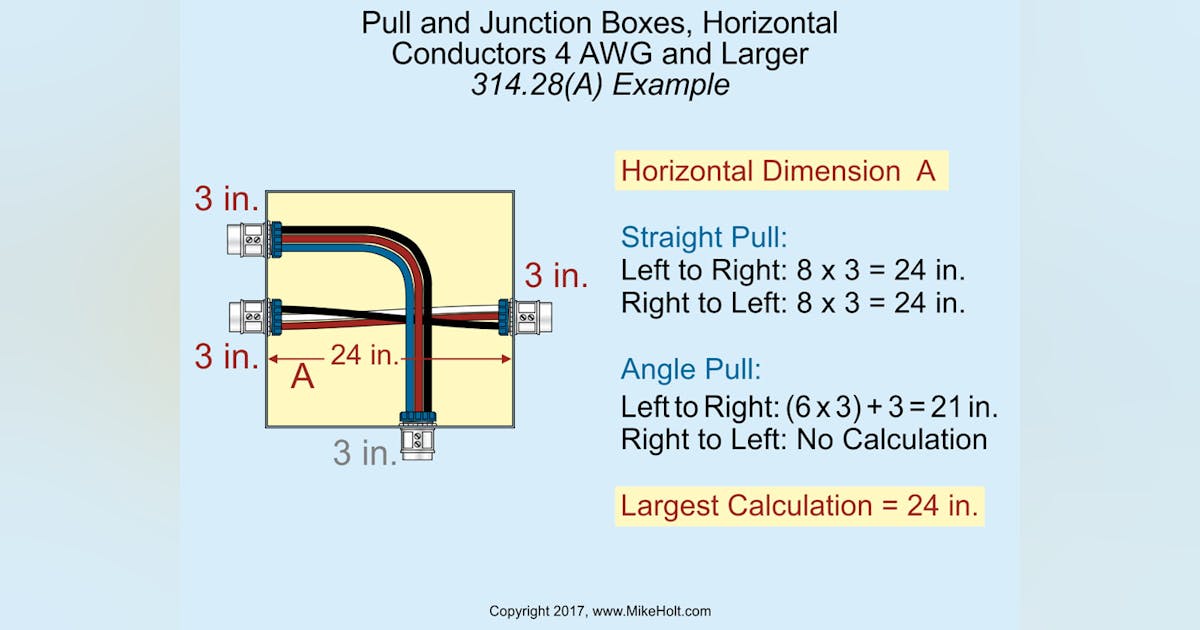

Until now, the easiest way to transport electricity from a power source to any equipment throughout a structure is through electrical wires. Connecting various devices like lighting fixtures and outlets to the power source means lots of cables to manage. Since we don't want our cables lying around the floor or within the walls and ceiling, we use conduits like tubings and pipes to keep the wires together organized. We then connect these conduits using connectors and boxes where we can reorganize the wires to direct them to the locations they need to be. We call these boxes our junction boxes or pull boxes as we pull wires to them before inserting them back into other conduits. Just like when choosing the correct wire sizes or wire gauges suitable for our electrical needs, these boxes should also have the appropriate dimensions to accommodate the wires that enter them. We'll also have enough room for the necessary bending of cables so we don't end up folding the wires sharply, which could damage their insulation. In the next section of this text, we will discuss the minimum requirements when choosing the proper junction box sizes. When discussing how to size junction boxes, it is best to consider some situational examples. Since we're dealing with horizontal straight pulls, we can determine the horizontal dimension of our junction box using this formula:. We use the same concept to determine the minimum height of our junction box if we're going to have vertical straight pulls in our junction box. However, our junction boxes may not only have straight pulls, but our junction boxes can also have angle pulls, U-pulls, and splices. For angle pulls, we use this formula to determine the dimension of the box parallel to the direction of the wire's path of entry:.

To size a pull box: Determine the size of the largest conduit for straight pulls and multiply that by 8. Toggle menu U-Pulls When conductors enter and leave from the same wall, the distance from where the raceways enter to the opposite wall is calculated with the same procedure used for angle turns: Six times the trade size of the largest raceway in a row, electrical pull box sizing.

Forums New posts Search forums. What's new New posts. Log in Register. Search titles only. Search Advanced search…. New posts. Search forums.

The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull. The National Electric Code NEC specifies the minimum size for cable tray systems which includes ladder, ventilated trough, ventilated channel, solid bottom and other similar structures. Raceways are included in another section of the code. Proper cable tray sizing is complicated and often existing cable trays are overloaded per the code. If you have questions or would like some engineering assistance to properly size your cable tray installation please contact us.

Electrical pull box sizing

Pull boxes are used along with conduit to simplify wiring installation , hence their name. They are made of sheet metal , cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive strain on the wire or insulation. Pull boxes allow long wiring runs to be installed in shorter intervals, and can be used for both straight and angled pulls. Although they have the same appearance as junction boxes, pull boxes do not have wiring connections inside. They are only access points for pulling and feeding conductors into a raceway system. Their use is mandatory in conduit runs where the number of bends between outlets exceeds the maximum number permitted by the NEC National Electric Code.

Mrs.poindexter

The sum of diameters for all other raceways on the same wall and row. Our junction box calculator can handle up to 10 additional conduits per row. Choosing the Right Underground Enclosures. Boxes and conduit bodies containing conductors 4 AWG or larger, and containing angle or U-pulls must be sized in accordance with the specifications of NEC article The rules in Need help choosing the right size pull boxes? It may not display this or other websites correctly. Straight pulls are when the conduit enters the box on one side, and leaves the box on the opposite side, as seen in the diagram below. Hopefully it is or People also viewed…. The lower LB must be steel. Can you cleverly get around this rule, by using reducing fittings to locally reduce its size, and using the reduced size for this calculation? However, before using it, please inspect the electrical plan of the junction box you wish to design.

Forums New posts Search forums. What's new New posts. Log in Register.

They are made of sheet metal , cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive strain on the wire or insulation. Log in. The rules in Please consult a qualified electrician before proceeding with any electrical installation. We didn't install the 2" run. New posts. Our junction box calculator can handle up to 10 additional conduits per row. Speaking of bending wires, you may be interested to learn something about "bend allowance," which is essential in forming metal sheets into different shapes such as a junction box. But it is still a good practice to always keep in mind to carefully bend your wires when reinserting them into their respective conduits to avoid damaging their insulations. They call for 6x the largest opening, so the 24" is necessary anyway, if I'm correct. I want to use a 24" long box so it's long enough to straddle past the center knockouts on two panels on 16" centers. This calculation is straightforward because there is only one possibility: six times the largest raceway plus the sum of the rest.

Brilliant idea and it is duly

What phrase... super, remarkable idea

In it something is. Thanks for the help in this question, can I too I can to you than that to help?