Fiberboard sheathing

What are the ingredients in fiberboard insulating sheathing or wall, ceiling, or roof sheathing used on or in buildings:.

Fiberboard was used indoors as both a finish-surface to be painted or as a base to which plaster and then paint were applied. This article describes and provides photographs that aid in identifying various insulating board sheathing materials used on building walls and roofs, such as Homasote, Celotex, Insulite, and Masonite insulating board sheathing products. InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website. Here we provide fiberboard product names and we describe the components, properties, and applications of various fiberboard, hardboard, and insulating board or sound deadening board products. Moisture uptake did not exceed 2.

Fiberboard sheathing

View All. We recommend the best products through an independent review process, and advertisers do not influence our picks. We may receive compensation if you visit partners we recommend. Read our advertiser disclosure for more info. Learn More. Matt Greenfield. Matt Greenfield is an experienced writer specializing in home improvement topics. He has a passion for educating and empowering homeowners to make informed decisions about their properties. Matt's writing focuses on a range of topics, including windows, flooring, HVAC, and construction materials. With a background in construction and home renovation, Matt is well-versed in the latest trends and techniques in the industry. His articles offer practical advice and expert insights that help readers tackle their home improvement projects with confidence. Whether you're a DIY enthusiast or a seasoned professional, Matt's writing is sure to provide valuable guidance and inspiration.

On the other hand, OSB has a rough texture and a flaky appearance, whereas plywood has fiberboard sheathing patchy finish. Patent 1,, Sept.

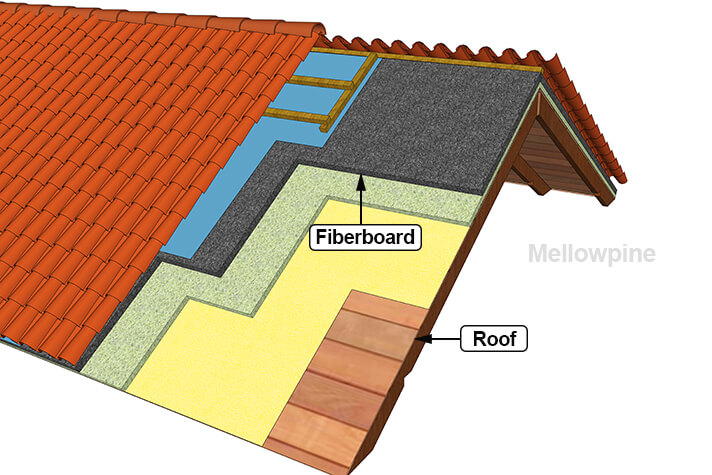

Structural exterior wall sheathing works with the building envelope to prevent wind and water from entering. Structural wall sheathing also ties framing studs together, makes the walls resistant to twisting and bending, and provides a surface for application of materials, like siding. However, many structural exterior wall sheathings, like OSB and fiberboard, lack sufficient strength, effective moisture management, may contain toxins, are difficult to handle, and have escalating and volatile pricing. Two common types of structural wall sheathing are oriented strand board OSB and fiberboard sheathing. They attach to the exterior wall framing and brace the walls against positive and negative forces. Both are wood products, which makes them earth friendly. However, there are several differences between OSB and fiberboard structural sheathing.

Fiberboard sheathing is easy and economical to install with hardboard, wood, or any other siding material. And, there is no fear of crushing when staples or nails are driven securely. Fiberboard sheathing withstands the wear and tear involved in handling prefabricated wall sections. And, because it doesn't break easily, there is less waste. Fiberboard sheathing is not adversely affected by inclement weather or sunlight. Fiberboard offers more sound transmission resistance than most sheathing materials.

Fiberboard sheathing

Fiberboard was used indoors as both a finish-surface to be painted or as a base to which plaster and then paint were applied. This article describes and provides photographs that aid in identifying various insulating board sheathing materials used on building walls and roofs, such as Homasote, Celotex, Insulite, and Masonite insulating board sheathing products. InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website. Here we provide fiberboard product names and we describe the components, properties, and applications of various fiberboard, hardboard, and insulating board or sound deadening board products. Moisture uptake did not exceed 2. Our photo shows bits of damaged fiberboard interior wall sheathing removed by the author [DF] during inspection and repair of a water-damaged area. Shown at the start of this article is brown fiberboard sheathing used to enclose a soffit overhang.

Dank relatable memes

Fiberboard sheathing releases small amounts of asphalt odor, especially when heated by the sun. Black fiberboard will often be coated in an asphalt water-resistant layer but other fiberboard, especially for indoor use may be tan, gray, brown, etc. Thank you. January 31st, 0 Comments. Multiple applications. Other advantages of fiberboard are:. Asbestos is not an "official" ingredient in fiberboard insulating sheathing. He has a passion for educating and empowering homeowners to make informed decisions about their properties. Not prone to twisting and bending motion. Where installed and fire-blocked to comply with Chapter 7, fiberboards are permitted as wall insulation in all types of construction. Carson Dunlop Associates provides extensive home inspection education and report writing material.

Structural exterior wall sheathing works with the building envelope to prevent wind and water from entering.

It is designed to fill the void of the outer walls. Comment Form is loading comments See the article above to read details and then don't hesitate to ask if that leaves you with any questions. Pros and Cons of Fiberboard Sheathing. Just ask us! Fiberboard is dimensionally stable, so resistant to expansion and contraction. What are the typical thicknesses of fiberboard over the last century? Thermo-Brace is an alternative corner bracing technique with structural ratings better than OSB and fiberboard. Fiberboard Structural Sheathing Fiberboard structural sheathing is an engineered product made with ground up wood chips and lumber waste glued together with an asphalt binder or resin. Produces more dust than regular fiberboards. Not prone to twisting and bending motion. It is an insulating material.

0 thoughts on “Fiberboard sheathing”