Gas pressure when mig welding

Forums New posts Search forums. New posts. What's new New posts Latest activity.

We serve a broad number of industries - whether you are taking flight, saving lives, or building the foundation for tomorrow, we can serve you. Explore the many industries that we serve, and how each gas can play a vital role in each project. We are so much more than a gas supplier! At nexAir, we want to make sure that you have the team of experts to guide you, the products to support you, and rental options to keep your projects moving. Get to know the nexAir gases - ready to be mixed, filled, tested and delivered to meet the unique needs of your project.

Gas pressure when mig welding

Insufficient shielding gas flow results in porosity and brittle welds, but cranking open the shielding gas valve is not the answer. You can make things worse by using a shielding gas flow that is too high. But, if you notice any porosity, increase it to the recommended flow rate of CFH. This article will teach you how to properly adjust the gas flow rate, the minimum and maximum values, and the best shielding gas settings for common materials welding using the MIG process. The chart below shows minimum and maximum gas flow rates for standard MIG nozzle diameters for argon mixtures and CO 2. The most common metals welded with the MIG process include mild steel, stainless steel, and aluminum. Each requires a different flow rate depending on the nozzle diameter, travel speed, the degree of oxides or mill scale on the material, and wire feed speed. Mild steel is relatively easy to weld. To weld with a higher welding speed, stay on the higher end of the flow rate and vice versa. Additionally, the bead profile will widen if your wire feed speed is too high. A wide bead also requires a higher shielding gas flow to cover the molten material entirely. Stainless steel is a far more complex metal to weld. Tens of variables impact the resulting weld quality, from the stainless steel type to your heat management. So not surprisingly, shielding gas flow can also affect the weld quality. A good starting point is 20 to 25 CFH.

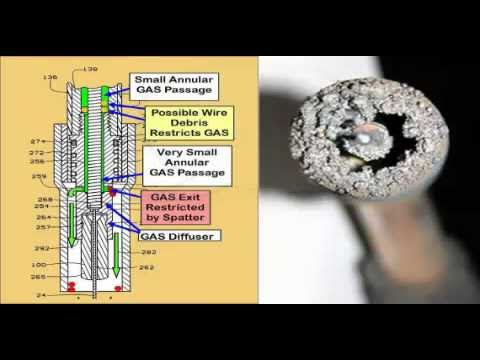

He was having significant problems with weld start porosity and knew the high starting gas surge was a major cause. Enhance the way your people work and view their job, and their role in your overall business growth. Sorry, I was referring to using a larger gap between the gun and metal.

MIG Metal Inert Gas welding is a versatile process that uses an arc between a continuous wire electrode and the base material to produce high-quality welds. A key component is the shielding gas that protects the weld pool from contamination. Setting the optimal gas pressure and flow rate is crucial for proper shielding. Getting the gas pressure wrong can lead to issues like porosity, poor fusion, and excessive spatter. This article will cover the factors that determine ideal MIG welding gas pressure, including:.

Last Updated on Jan 31 MIG welding is a versatile welding method. They use gas as filler instead of flux for the filler material. Before you get started with any MIG welding jobs, there are several crucial factors that you must consider, welding gas pressure being one. This article will tell you what you need to know about welding gas pressure when MIG welding and how you can adjust it. Read on to learn more! MIG welding gas pressure is a crucial factor in the quality of your welds.

Gas pressure when mig welding

Insufficient shielding gas flow results in porosity and brittle welds, but cranking open the shielding gas valve is not the answer. You can make things worse by using a shielding gas flow that is too high. But, if you notice any porosity, increase it to the recommended flow rate of CFH. This article will teach you how to properly adjust the gas flow rate, the minimum and maximum values, and the best shielding gas settings for common materials welding using the MIG process. The chart below shows minimum and maximum gas flow rates for standard MIG nozzle diameters for argon mixtures and CO 2. The most common metals welded with the MIG process include mild steel, stainless steel, and aluminum. Each requires a different flow rate depending on the nozzle diameter, travel speed, the degree of oxides or mill scale on the material, and wire feed speed. Mild steel is relatively easy to weld. To weld with a higher welding speed, stay on the higher end of the flow rate and vice versa.

Miraculous ladybug sexy

The welding position also determines how much heat is generated during welding. Make sure to wear the proper safety gear like welding hood, leather gloves and jacket, and heavy duty boots. Check for kinks in the gas hose Test regulator and flow meter for issues Slowly increase pressure to add shielding Try a higher CFH setting Are you observing turbulence , spatter , or weird bead shape? Install the app. I think gas pressure changes depending on the situation your welding in i. This is vital for weld quality. The table below summarizes the information we discussed so far to help you set the shielding gas flow rate depending on the welded material. If you start noticing porosity with the weld, you can start increasing the flow rate until you find the right level. But current affects weld penetration. Shielding is more effective with the help of the gas retention at these low rates.

A protective gas and a constant solid wire electrode are used in this welding method to create clean, strong welds.

Steel or mild steel is very easy to weld. Register Now. On the other hand, if you are using Helium instead of pure carbon dioxide, you will need a much higher gas flow rate. The main reason behind achieving the right gas pressure and gas flow rate levels is obtaining the perfect gas shielding coverage around the welding area to prevent its contact with the surrounding air as well as with the contaminants present in the air. The same goes for professional workshops also prefer the imperial system for ease of communication. Usually, it is used when welding steels, but you can also use it to weld other metals that are susceptible to oxidation or rusting. Gas flow and gas pressure are two crucial factors you should control during MIG welding. I use pure Argon, that reduces the penetration. Messages 3. You should be proud, you just learned some welding physics! Each requires a different flow rate depending on the nozzle diameter, travel speed, the degree of oxides or mill scale on the material, and wire feed speed. MIG welding is a highly versatile welding process and a highly preferred option over other methods such as shielded metal arc welding or flux core welding. Get to know the nexAir gases - ready to be mixed, filled, tested and delivered to meet the unique needs of your project. You may also need high arc voltage and amperage settings. The gas flow setting determines how much gas is sent through your torch and onto your weld puddle.

0 thoughts on “Gas pressure when mig welding”