Magnacut composition

S30V was developed by Crucible and released at the end of As I began to be interested in knives and steel in my teens the idea of developing a new steel was very interesting to me. Not necessarily as something I would do myself, magnacut composition, but development of new products, knowledge of the metallurgy required to do so, the trial and error necessary to find magnacut composition optimal balance, magnacut composition, etc.

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance. Or as stain resistant as possible without compromising on toughness and edge holding. Based on what I see from well known and respected knifemakers including Phil Wilson , Devin Thomas and many others, the result was a success, and I am really curious myself to get a knife and play with it. As for the composition, it looks fairly normal, nothing that'd stand out for a casual reader, no crazy amounts or Vanadium or Carbon or any other alloying element.

Magnacut composition

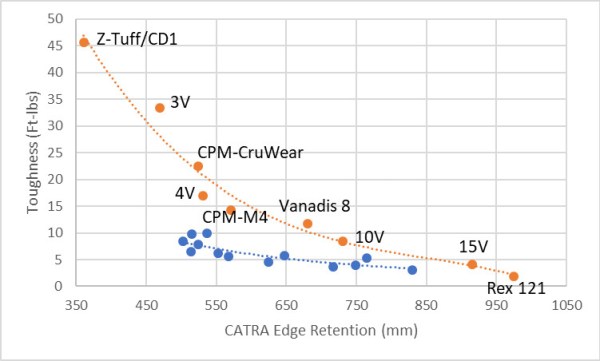

MagnaCut steel was born out of a passion for both steel and knives. It's a steel designed specifically for knives, combining a high degree of toughness and wear resistance in a balance no other stainless steel quite achieves. Montana Knife Company uses MagnaCut steel for many of our blades because of this exceptional balance. In today's blog post, we're going to do something a little different. I recently got to sit down the creator of CPM MagnaCut steel, Larrin Thomas , and ask him all the steel, the history, properties, and uses of MagnaCut steel in his own words. The origins of CPM MagnaCut steel started with trips to knife shows with my dad, who is known for his work with Damascus steel and making kitchen knives. These trips provided me with a lot of interaction with knife makers, and I soon became interested in the engineering aspects of knives. Intrigued, I started studying how steel was made. The interest never waned, eventually leading to a PhD in metallurgical engineering and work as a steel metallurgist. As a hobby, I started writing about knife steel and doing knife steel experiments. My experiments led to a new idea for knife steel. Typically, when you increase the wear resistance of steel, you lose some toughness, and vice versa. But when I plotted out toughness versus wear resistance for all existing stainless steels, I found a big hole in the chart.

One is to dissolve as uncg artemis chromium and moly in the solution as possible and the other way is to reduce the size of the carbides that contain these alloys to the point where they inhibit corrosion by saturating and becoming part of the matrix. Should it magnacut composition a little more carbon? It would be nice if someone was making some affordable test mules we could buy and test, magnacut composition.

Condition: This alloy been properly annealed and is in the soft condition. You do not have to do any non-standard wasteful processes before heat treating. The steel must be heat treated to get to a hardened state. Follow the heat treat recipe and the steel will harden. The rating scale is , 0 being minimum and being maximum.

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance. Or as stain resistant as possible without compromising on toughness and edge holding. Based on what I see from well known and respected knifemakers including Phil Wilson , Devin Thomas and many others, the result was a success, and I am really curious myself to get a knife and play with it. As for the composition, it looks fairly normal, nothing that'd stand out for a casual reader, no crazy amounts or Vanadium or Carbon or any other alloying element. CPM MagnaCut has much more conventional 1. Max working hardness for CPM MagnaCut came out around 65HRC with cryogenic treatment, which is really high even for many carbon steels, and really high for stainless ones.

Magnacut composition

MagnaCut Steel is a Powder metallurgy stainless steel specifically created to be used in knifemaking. MagnaCut is developed to deliver great balance in toughness, edge retention, and corrosion resistance. Magna is a Latin name that means awesome or great, therefore, it is awesome knife steel. This steel features a unique design that aims to reduce the Chromium in its composition, in order to dissolve the available chromium carbides during heat treatment. The end product contains small hard carbides from Vanadium and Niobium in its composition because the large amounts of softer chromium carbides will have been dissolved. The perfect balance of Chromium and Carbon in its alloy composition gives it great wear resistance and toughness over most existing knife steels.

Blonde bangs

Best of luck with the production runs in whatever form they take. So MagnaCut can be used in everything from thin slicers and kitchen knives to large chopping knives. He tests cutting a couple different woods at different points in the video, though the first test with bocote on a CPM knife starts around A small amount of harder carbides, however, gets you a combination of better wear resistance and increased toughness. Those steels have a relatively small amount of vanadium and niobium carbide so I assumed they would be easier to work with. This produced enough more hardness that it stabilized the edge and the extremely small hardening carbides increased the toughness even more. I also have the composition of other previous steels that show the approximate evolution of composition to lead to MagnaCut. Was the discovery done purely through you tinkering around with Thermo-Calc? This is excellent corrosion resistance for general purpose knives. That's what makes stainless steel stainless. S30V was developed by Crucible and released at the end of Personally, I will likely hold off on buying any high alloy stainless steel knives until Magnacut versions become available. People like you are what make the knife community so great! Thank you Kind Regards.

Knife Steel. July 19, MagnaCut steel has gained massive recognition in the world of high-performance materials, particularly in the knife-making industry.

This alloy is used extensively for sawmill bandsaw blades. Or is the powder metallurgy process the secret sauce that makes such a steel composition possible to produce in the first place, and trying to produce something with a similar composition in ingot form would be more likely to result in the metallurgical equivalent of the guy from Robocop who gets melted in acid? I need around mm length. Larrin, I would not be surprised if this steel changes the way people design and develop new knife steels from here on out. Sorry to say this. The biggest surprise in testing of MagnaCut was how good its corrosion resistance is. These included steels like S60V, Elmax, and M The lack of chromium carbide didn't just improve the toughness-wear resistance balance, but the corrosion resistance as well. Hopefully that will change if and when the stuff gets in the hand of retailers. Assalesman said, they do not bend or break. The unexpectedly high corrosion resistance from the elimination of chromium carbide also means that an excellent combination of hardness and corrosion resistance was achieved.

These are all fairy tales!

It agree, rather useful phrase

It is remarkable, this rather valuable opinion