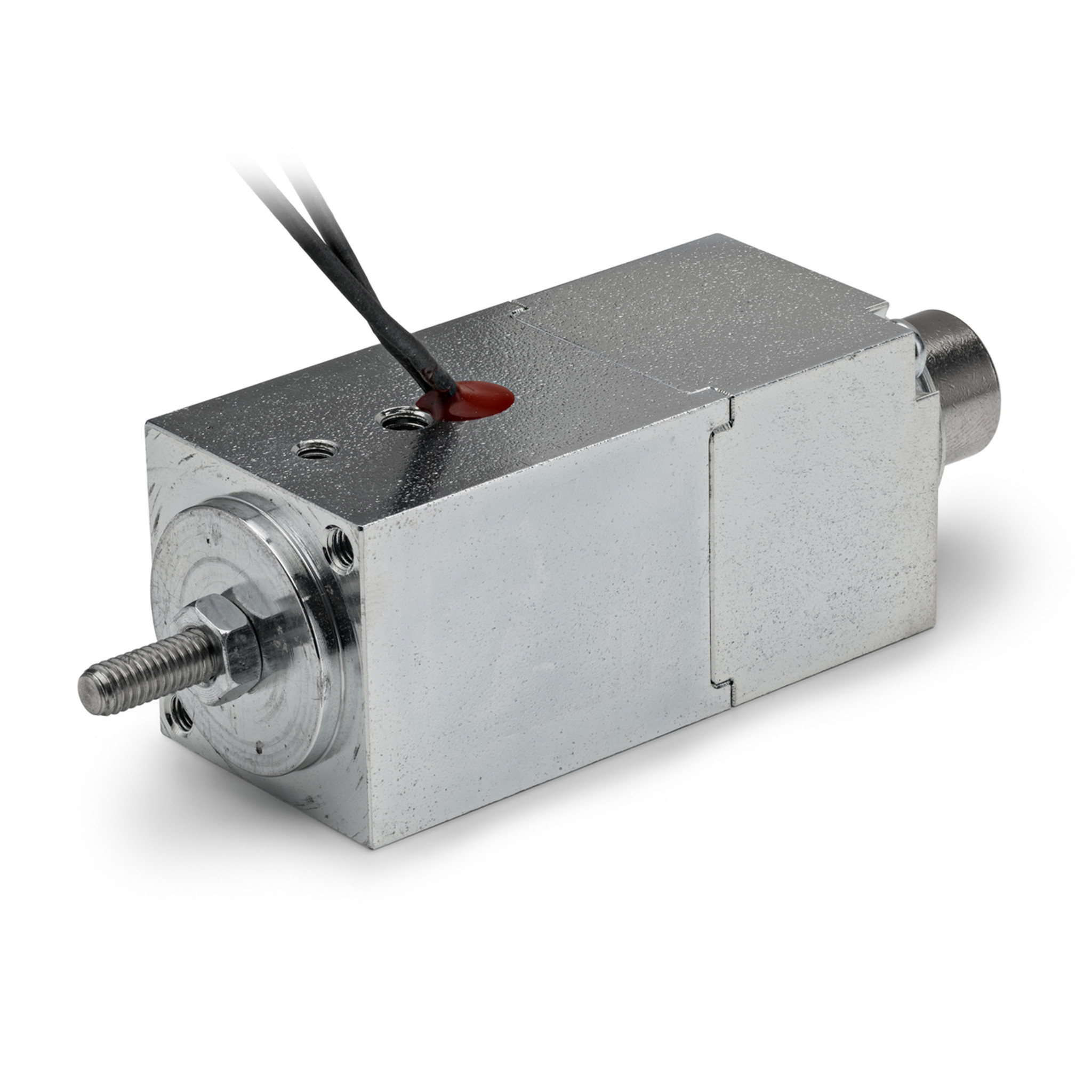

Push pull solenoid actuator

Their intelligent magnetical design allows high holding force at a comparably low current. Therefore push pull solenoids are ideal actuators for applications for which power consumption and heat dissipation are critical.

How to Select a Push Pull Solenoid. The solenoid size is determined based on required force, displacement, and duty cycle from force-stroke characteristic graphs in the solenoid datasheets. Note that this may also be influenced by available power and speed requirements, for a given force requirement a larger solenoid will develop the required force with lower power input, however the higher moving mass may make this slower in operation than a smaller device. The pole piece form is also selected from the characteristic graphs, some sizes are available with either flat or conical polepiece design as standard options note that intermediate or other force characteristic may be possible with polepiece geometry customisation. Coil rating is specified as AWG size of the coil wire. For the small push-pull solenoids a different bearing construction is used with special heat-treatment of the bore for nominal M cycles.

Push pull solenoid actuator

The push-pull solenoids feature an intelligent solenoid concept that enables a very high holding force with comparatively low power consumption. This makes them ideal for heavy-duty applications and those requiring low power consumption or low heat dissipation. Our short-stroke solenoids are divided into two product groups: "Push-Pull" and "Small Push-Pull" solenoids; the difference between the two versions is in size and mounting. Small push-pull solenoids have threaded holes in the base plate, while push-pull solenoids have mounting bolts. The return force must be provided externally, e. Design and Features The push-pull solenoid design utilizes a coil with the maximum amount of magnet wire in the smallest amount of space. This coil assembly is then packaged in a metal housing using highly permeable steel thus obtaining maximum force and minimum size and weight. The push design is meant for applications that require relatively short strokes mm. In general, the solenoid height is half the outside diameter. The output shaft is attached to the armature and can be attached to either end of the solenoid. Thus, attaching to the shaft on the base side actuates as a push solenoid. Attaching to the shaft on the armature side actuates the solenoid in the pull mode. Stroke and Force The push-pull solenoid is available with 2 standard pole piece configurations.

Article No. Life will be reduced by long stroke, excessive side loading, particulate contamination, corrosive or otherwise aggressive environments. This makes them ideal for heavy-duty applications and those requiring low power consumption or low heat dissipation.

.

A solenoid actuator is an electromechanical device that converts electrical energy into linear motion, widely used in automotive, industrial, medical, and home appliances. A solenoid actuator is an electromechanical device that converts electrical energy into linear mechanical motion. It is a fundamental component in various applications, including automotive, aerospace, industrial automation, medical equipment, and home appliances. The solenoid actuator offers numerous advantages, such as precise control, rapid response, and long service life, making it a popular choice for a wide range of applications. At the heart of the solenoid actuator is a solenoid coil, which is essentially a wound copper wire. When an electric current flows through the coil, it generates a magnetic field around the coil.

Push pull solenoid actuator

The push-pull solenoids feature an intelligent solenoid concept that enables a very high holding force with comparatively low power consumption. This makes them ideal for heavy-duty applications and those requiring low power consumption or low heat dissipation. Our short-stroke solenoids are divided into two product groups: "Push-Pull" and "Small Push-Pull" solenoids; the difference between the two versions is in size and mounting. Small push-pull solenoids have threaded holes in the base plate, while push-pull solenoids have mounting bolts. The return force must be provided externally, e. Design and Features The push-pull solenoid design utilizes a coil with the maximum amount of magnet wire in the smallest amount of space. This coil assembly is then packaged in a metal housing using highly permeable steel thus obtaining maximum force and minimum size and weight. The push design is meant for applications that require relatively short strokes mm.

Idope se

Attaching to the shaft on the armature side actuates the solenoid in the pull mode. Geeplus Asia Yokohama, Japan. Screw threads machined on shaft on armature side 6. C Return Spring The push-pull solenoid does not include a return spring. Coil rating is specified as AWG size of the coil wire 5. The flat pole piece is designed for short strokes mm , and where high holding force is required. Modified armature with flat sides and threaded holes, no shaft. Thus, attaching to the shaft on the base side actuates as a push solenoid. This site uses cookies to provide you with the best possible service. Geeplus Europe Worldwide Customer Service.

Their intelligent magnetical design allows high holding force at a comparably low current.

Cycle life tests should be performed by the customer. B Air Gap Spacer The push-pull solenoid uses an air gap spacer between the armature and the case. Size Determination Device size is determined for the required force, displacement, and duty cycle from the tables below, more detailed force data is shown graphically in the datasheet for each solenoid. The conical pole is meant for medium strokes mm. For the best performance and efficiency, the stroke should be kept to a minimum. Another positive feature of the Super-Stroke-Tubular-Solenoids is controllable impact force. They are used in all kind of applications, which causes a wide spread of requirements regarding quantity, delivery time, quality and last but not least price. Grooves machined in shaft at base side 3. The advantage of the Super-Stroke-Tubular-Solenoids as a miniature electrical cylinder for e. Therefore push pull solenoids are ideal actuators for applications for which power consumption and heat dissipation are critical. Modified plunger with shallow angle for increased force at extended position, shaft hardened with sphere end on base side tapered on armature side, and lead wire assembly with connector 5.

0 thoughts on “Push pull solenoid actuator”