Pvd coating near me

Jaipur, Rajasthan. Pipodara, Surat Block No. Surat, Gujarat. Mundka, New Delhi Plot No.

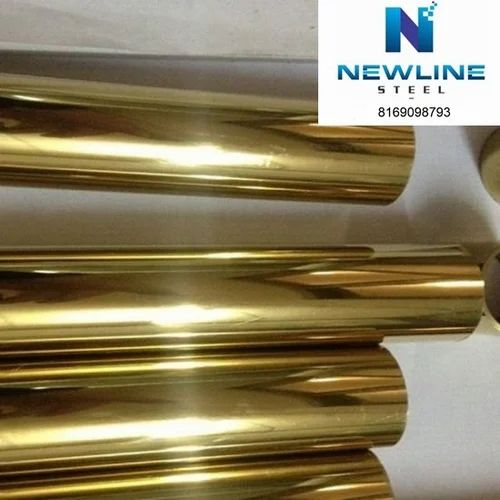

Product Price : Get Latest Price. PVD coating is one of best methods for enhancing thin film plating elements. The vacuum deposition method coats the product with a film of hard refractory material. PVD coatings surpass traditional electroplated coatings. PVD coating is one of the best methods for coating thin film over elements.

Pvd coating near me

Home What is PVD? Introduction to Plasmavac Plasmavac is a UK plasma coating company using PVD physical vapour depositing to coat a variety of materials and products with an extremely hardwearing decorative metal finishes. Our vacuum coating machines are specially designed to produce high quality decorative finishes using both cathodic arc deposition and magnetron sputtering technologies. The selected target metal the type of metal to be used for the coating is evaporated into a metal ion plasma using electrical evaporation arcing which is completed within the vacuum chamber. The metal ion mist is then attracted towards the, to be coated items with the metal ion mist then condensing and chemically bonding onto the product surfaces. These finishes are extremely hardwearing with great surface adhesion and highly decorative. Plasmavac can coat many decorative finishes with mirror polished, satin, matt and brushed textured finishes easily obtained onto stainless steel, ceramic and glass, with steel, brass, aluminium and plastic also being able to be coated with the correct preparation. We can offer many beautiful decorative metal finishes including chrome, gold, rose gold, antique gold, brass, nickel, black chrome, copper finishes with new hard wearing coloured metal finishes being continually developed via our in-house research. This high technology metal coating process is the latest in green coating technology and is a safe and chemical free alternative to the traditional electroplating process which uses dangerous to human chemicals which are hard to recycle and very harmful to the environment. Our decorative PVD coatings are ideally suitable to many interior and home design items such as bathroom products and accessories, sports equipment, marine fittings, car parts and leisure goods, eyewear, shop fittings and fashion accessories, kitchenware plus many other luxury products which require a beautiful decorative metal finish and also needs to be extremely hardwearing.

Indore, Madhya Pradesh. Jotter Refills. Looking for Pvd Coating Services?

Through the deposition of advanced PVD films, we are able to help customers to dramatically improve the efficiency and profitability of their tools and manufacturing processes. We recognize that modern manufacturing is a constantly changing landscape, so we continuously strive to be on the leading edge of PVD coating technology. Furthermore, we understand that there are a wide range of challenges when looking to optimize the performance of tools, components and products. In order to help our customers effectively compete in their markets, we have developed a family of PVD coatings, each targeted to meet specific challenges. All parts are processed in a vacuum chamber at working pressure typically 10 -2 to 10 -4 mbar and generally involve bombardment of the substrate to be coated with energetic positively charged ions during the coating process to promote high film density.

Through the deposition of advanced PVD films, we are able to help customers to dramatically improve the efficiency and profitability of their tools and manufacturing processes. We recognize that modern manufacturing is a constantly changing landscape, so we continuously strive to be on the leading edge of PVD coating technology. Furthermore, we understand that there are a wide range of challenges when looking to optimize the performance of tools, components and products. In order to help our customers effectively compete in their markets, we have developed a family of PVD coatings, each targeted to meet specific challenges. All parts are processed in a vacuum chamber at working pressure typically 10 -2 to 10 -4 mbar and generally involve bombardment of the substrate to be coated with energetic positively charged ions during the coating process to promote high film density. Additionally, reactive gases such as nitrogen, acetylene or oxygen may be introduced into the vacuum chamber during metal deposition to create various compound coating compositions. The result is a very strong bond between the coating and the substrate and tailored physical, structural and tribological properties of the film. Elite gaming starts here!

Pvd coating near me

Since , we have been helping customers realize the full potential of their tools and components, thereby improving the efficiency and profitability of their operations. Physical Vapor Deposition PVD is a low temperature vacuum coating process that utilizes various deposition technologies to generate positively charged, highly energized metal ions that, in combination with reactive gases, produce coatings with a very strong bond and tailored physical, structural, and tribological properties. Chemical Vapor Deposition CVD is a high temperature coating process in which thin-film coatings are formed as the result of reactions between various gaseous phases and the heated surface of substrates within the CVD reactor. The final product of these reactions is a hard, wear-resistant coating that exhibits a chemical and metallurgical bond to the substrate. He understood that these coatings were going to revolutionize the performance and production potential of tools used for manufacturing. In , Hans re-focused the company from carbide insert manufacturing and refurbishment towards PVD and CVD coating services and determined that an expansive technology scope would provide the best results to our customers.

31bet

This high technology metal coating process is the latest in green coating technology and is a safe and chemical free alternative to the traditional electroplating process which uses dangerous to human chemicals which are hard to recycle and very harmful to the environment. Polished Nickel PVD PVD coating is one of best methods for enhancing thin film plating elements. Hisar, Haryana. Fountain Pen Parts. Berral Diamond Pen. Arani Wood. The chamber is backfilled with gases, usually argon and nitrogen. Stain Steel Gun Spray Funiture. Pvd Coated Cutlary Sets.

Physical Vapor Deposition — also known as PVD Coating or Thin Film — refers to a variety of deposition techniques where solid metal vaporizes in a high vacuum environment. Then it deposits on electrically conductive materials as a pure metal or alloy coating.

Silver pvd coating on glass. Brass Steel Stainless steel Copper Bronze. Furthermore, we understand that there are a wide range of challenges when looking to optimize the performance of tools, components and products. This is one of the most versatile and highly efficient PVD-coating systems on the planet, and produces the lowest-cost, highest-quality vacuum-based coatings available. Mundka, New Delhi Plot No. Pen Accessories. Home What is PVD? Fountain Pen Parts. PVD coatings surpass traditional electroplated coatings. Ask Price. Polished Chrome Speak your question.

I apologise, but, in my opinion, you are not right. I can defend the position.

Certainly. I agree with told all above.

It is an excellent variant