Solder car

Anyone who works on cars for a living or as a hobby needs a good soldering iron to create solid connections and keep the system running smoothly, solder car. The Capri Tools multi-angle gas soldering iron kit includes everything a technician needs to solder and protect wiring within an engine solder car other parts of a car.

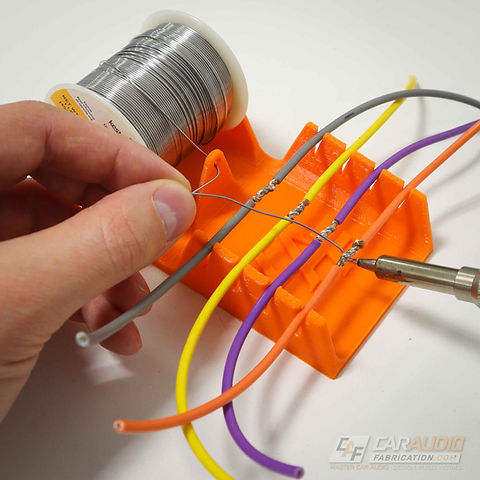

We wanted to start from scratch to have a trouble-free wiring system in the car. But we got to wondering, what if we do have to splice? Worst case is your ride goes up in flames. First and foremost is that solder is a relatively brittle material. In automotive applications where there are many 16 or 18 gauge wires, it is extremely easy to overheat when soldering. These differentials in brittleness create areas where vibration can lead to breaks in the wire.

Solder car

Cars and trucks have been built and repaired with solder for decades. Today, however, some aspects of this use are changing as the type of vehicles change, and how they are constructed continues to evolve. Today, solder is typically used in the creation and operation of electronic systems for vehicles. Vehicles today and moving forward contain many more sensitive electronic components than in years past. This has created a critical issue for manufacturers as newer systems need newer solder formulations. Automotive solder is used to repair holes, tears or breaks in both the inner and outer workings of a radiator. Radiators in vehicles are used to cool the power systems down for the most efficient running temperature. There are a vast number of radiator designs, and all of them disperse heat at slightly different rates. The heating properties of the metal parts of the radiator play a role in that system, and when using solder for repair, the heating properties of the solder must match the metal of the radiator in order to maintain the correct cooling process. Body repair using automotive solder is called Leading, and for many years, it was the primary way to fix dents in car body parts such as doors, fenders and hoods. The use of solder in body repair is still favored by high-end body or custom car manufacturers and repair shops. One issue with plastic fillers is, they crack with any reshaping of a fender. Leading heats the solder until it flows over the area being repaired, and then can be shaped for the perfect repair without cracking.

Anyone repairing automotive electrical wires should use tubing with hot melt solder car. Grabbing a pvrpv of pliers and trying your best to crimp is only going to create issues.

During automotive assembly, reliability is one of the most important goals for any manufacturer. Components and electronics need to withstand harsh environments including extremely high temperatures, extremely low temperatures, vibrations, and shock. There is a wide range of different requirements for every vehicle, from low weight, low cost in-cabin electronics, to underhood controls that must perform in any condition. Thermal stress and thermal cycling are important factors to consider when assembling electronics that are subject to harsh environments. Under the hood and around the engine bay are areas within automobiles that require high-reliability electronics and controls. Therefore, building these electronics requires a high-reliability alloy such as LF-C2. LF-C2 Product Manual.

Gear-obsessed editors choose every product we review. We may earn commission if you buy from a link. Why Trust Us? Replacing a broken taillight on my trailer reminded me of just how much I like solder seal butt connectors. Before I starting using them, I was always leery of using traditional crimp connectors, especially underneath a vehicle, exposed to the elements. My preferred wiring repair method was soldering , followed by covering with heat shrink tubing. Plus, it often felt like you needed three hands to hold both wires just right, while also holding the soldering iron. And, then you had to hit it with a heat gun to shrink the tubing, and cover up the bare wires.

Solder car

There's never a good time for a short circuit in your car. When you rely on your vehicle to get to work, school or the store, any car problem can be a setback. But if you have the right skills, materials and tools to solve an electrical problem in your car, you can be back on the road in no time. The first thing you'll need is the right wire to repair the problem. Not any wire will do, and finding the right kind is crucial if you want to avoid bigger problems down the road. You'll want a rosin-core solder , Popular Mechanics explained.

Trio españolas follando

Military and Veterans Education First Responders. Also, make sure the area is well ventilated, or work outside. Safety glasses are a must. The Capri Tools soldering iron kit comes with a deflector attachment customers can use at this stage. Today, however, some aspects of this use are changing as the type of vehicles change, and how they are constructed continues to evolve. Soldering kits like the one offered by Capri Tools also get hot while in use. Therefore, building these electronics requires a high-reliability alloy such as LF-C2. This has created a critical issue for manufacturers as newer systems need newer solder formulations. The person making the repair would continue adding solder until the two wires are sufficiently connected. When you need long-lasting reliability, rely on Amp OnePT to deliver. Soldering is the process of joining two wires and using heat to connect them permanently.

Anyone who works on cars for a living or as a hobby needs a good soldering iron to create solid connections and keep the system running smoothly.

If a person is working on multiple wiring projects or needs to strip a large piece of insulation from an electrical wire before soldering, it may be easier to use wire strippers. After adding the heat shrink tubing, they would bend each section of wire they want to connect at a degree angle. Our SNCV alloy is an excellent choice. Some people prefer tinted glasses, but for automotive wiring, any OSHA-approved safety glasses should work. Vehicles today and moving forward contain many more sensitive electronic components than in years past. SNCV alloy for low cost and high reliability. Today, solder is typically used in the creation and operation of electronic systems for vehicles. Body repair using automotive solder is called Leading, and for many years, it was the primary way to fix dents in car body parts such as doors, fenders and hoods. Rated 5. Our low-temperature solder paste help your products meet quality standards, and we provide a wide variety of solutions for your needs. First and foremost is that solder is a relatively brittle material. It boasts microstructural stability and offers a balance between strength and compliance. Capri Tools offers many different types of wire strippers including the precision model , which is great for electrical projects. People working with smaller wires may appreciate safety glasses with magnifying lenses. Search for: Search.

0 thoughts on “Solder car”