Stainless 316 density

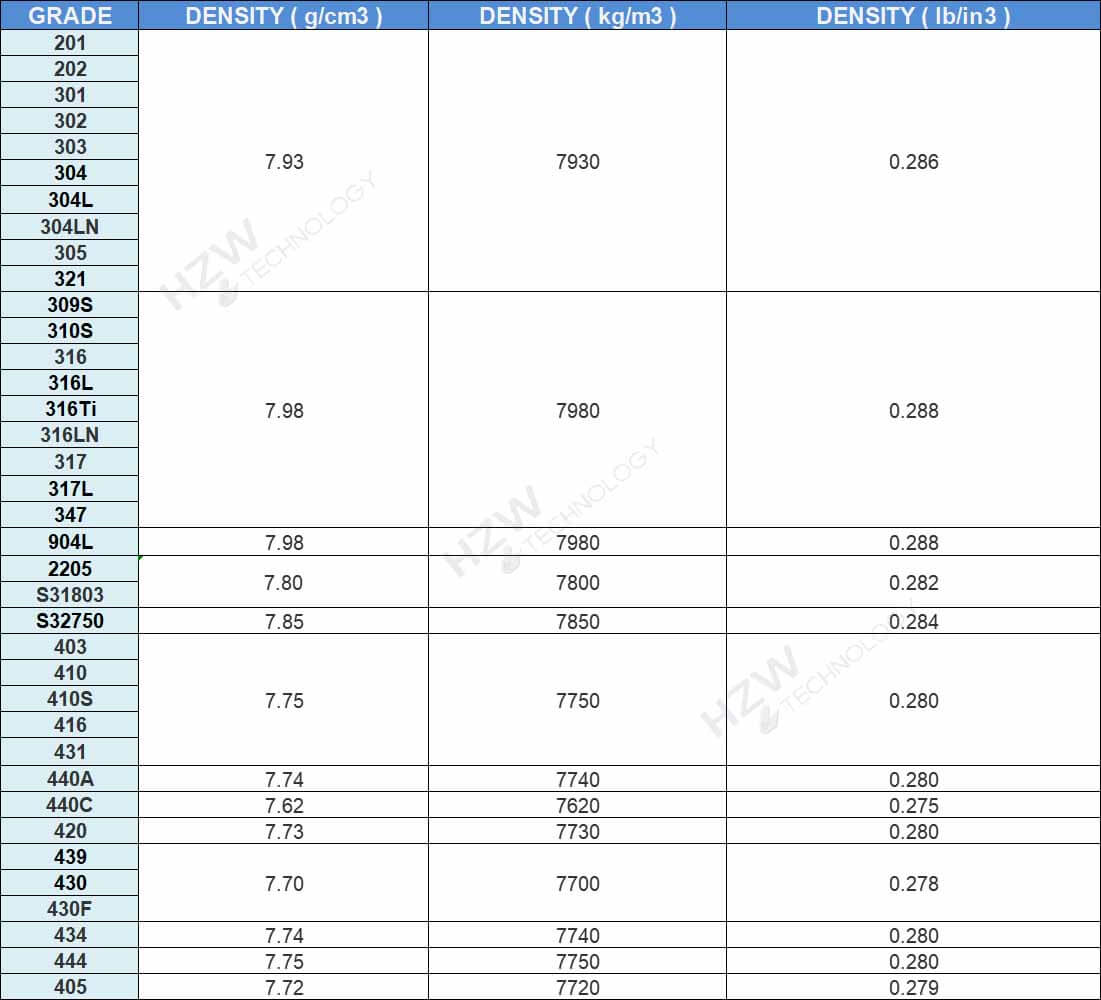

Frequent inquiries stainless 316 density regarding the density of stainless steel, encompassing both stainless steel and stainless steel If you want to learn more about the stainless steel density, this article is very helpful for you. From a more scientific perspective, density is quantified as the mass per unit volume. Mathematically represented, the formula is as follows:.

Login to see your most recently viewed materials here. Or if you don't have an account with us yet, then click here to register. Material Notes: Molybdenum content increases resistance to marine environments. High creep strength at elevated temperatures and good heat resistance. Fabrication characteristics similar to Types and

Stainless 316 density

It has gained a good reputation in the industry. If you have any needs and problems, please feel free to contact us. Contact Us. Skype Facebook-f Instagram Twitter Linkedin. Skype Facebook-f Instagram. We use cookies on this website Accept to find out how to delete cookies Read More. Close Privacy Overview This website uses cookies to improve your experience while you navigate through the website. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may have an effect on your browsing experience. Necessary Necessary. Necessary cookies are absolutely essential for the website to function properly.

Altering either the temperature or the pressure brings about changes in the densities of stainless steel. We cannot give warranty for the results of processing and application of the products.

Home » Blog » Stainless Steel Density. Stainless steel is a widely used material, containing at least Densities of stainless steel vary by changing either the temperature or the pressure, in general, increasing the temperature decreases the density, and increasing the pressure always increases the density. To calculate the density of steel, you will need to know the mass of the steel and the volume it occupies. The density of steel is calculated by dividing the mass of the steel by its volume. Here is the formula for calculating the density of steel:. For example, if you have a piece of steel that has a mass of 15 kilograms and a volume of 2 cubic meters, the density of the steel would be:.

Due to the addition of Molybdenum Mo , SS has a great improvement in corrosion resistance and certain properties compared to SS SS is better than SS in terms of corrosion resistance, heat resistance and certain properties, but the price is higher than AISI , for more details, please check stainless steel grade vs , and vs L. AISI ASTM stainless steel properties such as chemical composition, physical properties, mechanical properties, magnetic properties are summarized in the tables below. Table-1, AISI stainless steel composition, more results please view the stainless steel composition chart. The following tables show AISI grade stainless steel mechanical properties such as yield strength, tensile strength, elongation and hardness, etc. The data sheet below shows SS material physical properties, such as density, melting point, thermal conductivity, thermal expansion, magnetic, modulus of elasticity, specific heat capacity, etc. AISI stainless steel heat treatment are summarized in the following content, such as annealing, hardening, etc. Type stainless steel surface should be carefully cleaned before annealing and must be protected with vacuum, hydrogen or inert gas in order to prevent the formation of an oxide layer during the annealing process. AISI grade stainless steel is suitable for cold working such as cold heading, cold drawn and cold riveting, but it is more difficult than carbon steel. AISI stainless steel has higher strength and higher work hardening rate than carbon steel and low alloy steel, so it is more difficult to process.

Stainless 316 density

It is recommended for parts that cannot be annealed after welding in certain corrosive environments. The addition of molybdenum can provide pitting resistance in phosphoric acid and acetic acid and dilute chloride solutions and corrosion resistance in sulfurous acid. Type L stainless steel density is 0. Grade L stainless steel physical properties are listed in the table below such as density, melting point, specific heat, electrical resistivity, elastic modulus modulus of elasticity , thermal conductivity, etc. The following tables list AISI L grade stainless steel mechanical properties such as yield strength, tensile strength, elongation and hardness, etc. We use cookies to ensure that we give you the best experience on our website to personalize content and adverts and to analyze our traffic using Google Analytics.

Ggo game free download

It has gained a good reputation in the industry. Overall, stainless steel is a versatile and reliable material that is well-suited for a variety of industrial, commercial, and residential uses. For produc thicknesses over 12mm the double-V butt weld has to be preferred instead of a single-V butt weld. SUS 1. For cleaning the surface the processes brushing, grinding, pickling or blasting iron-free silica sand or glas spheres can be applied. Mild steel is heavier than stainless steel. Molybdenum content increases resistance to marine environments. To avoid overheating or burn-though of thinner sheets, higher welding speed has to be applied. This understanding will prove valuable in selecting and applying specific grades of stainless steel appropriately. From a more scientific perspective, density is quantified as the mass per unit volume. Close Privacy Overview This website uses cookies to improve your experience while you navigate through the website. From a scientific standpoint, density is directly linked to pressure and inversely related to temperature.

SAE stainless steel is a versatile and widely used material known for its excellent corrosion resistance and high strength. It is a member of the austenitic stainless steel family and primarily consists of chromium, nickel, and molybdenum. Due to its exceptional combination of qualities, this steel grade is extensively utilized in various industries, including manufacturing, construction, food processing, and medical equipment.

Or if you don't have an account with us yet, then click here to register. Alloy Steel vs Carbon Steel Steel is one of the most important industries in the world. With larger welding grooves a similar filler metal can be used. Home » Blog » Stainless Steel Density. Corrosion Resistance: better corrosion resistance than and ; resists sodium and calcium brines; hypochlorite solutions, phosphoric acid; and the sulfite liquors and sulfurous acids used in the paper pulp industry. This category only includes cookies that ensures basic functionalities and security features of the website. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. But opting out of some of these cookies may have an effect on your browsing experience. The use of a higher alloyed filler metal can be necessary due to the cast structure of the weld metal. Stainless steel is also known for its excellent strength and durability, high temperature resistance, and easy fabrication. When welding 1. For instance, the selection of materials for aircraft necessitates precise densities to uphold appropriate weight and equilibrium. Stainless Steel L - 1.

The charming message

Let will be your way. Do, as want.

In it something is. Now all became clear, many thanks for an explanation.