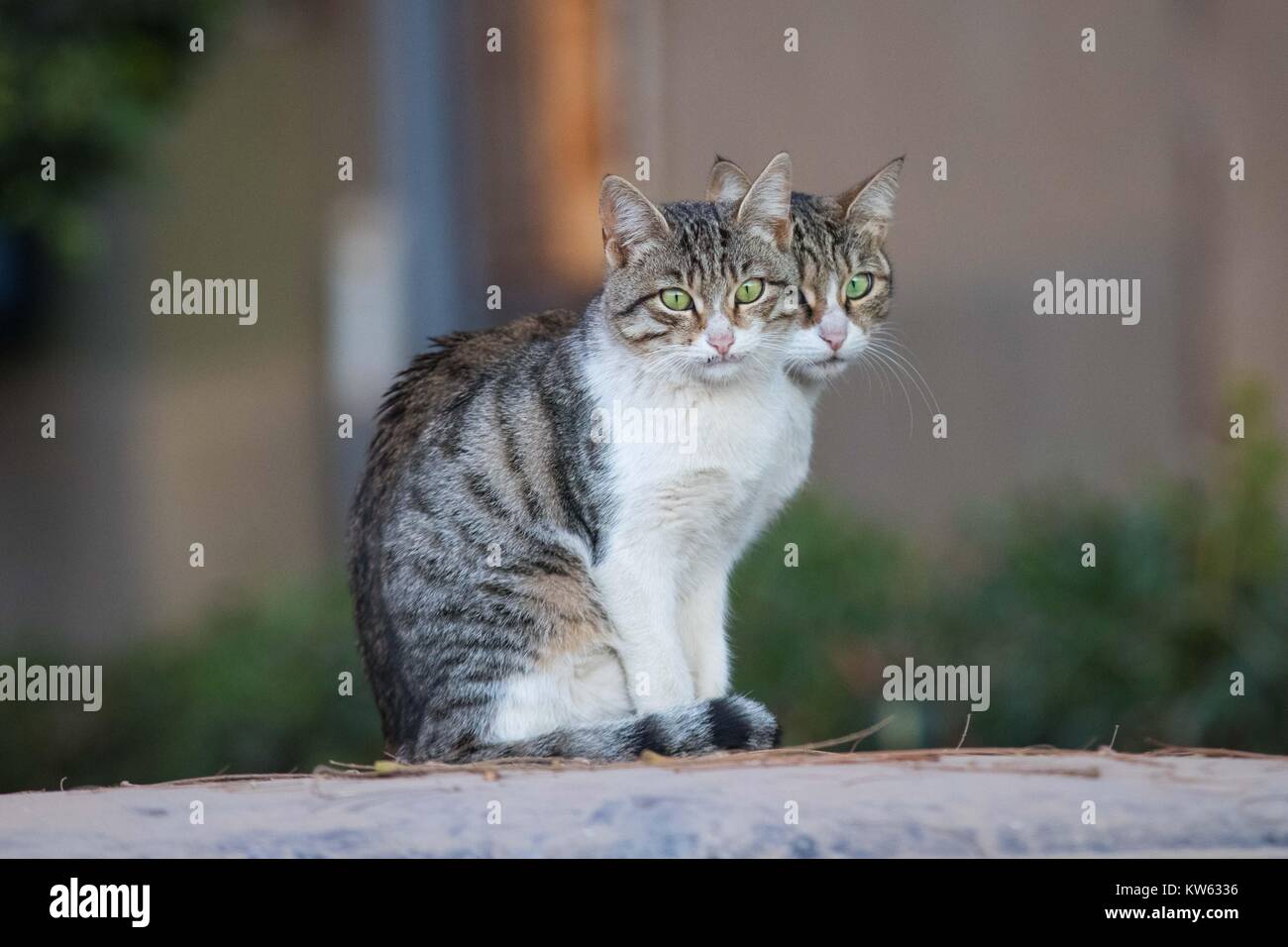

Twin cat

Absolutely yes! By utilizing two function blocks, twin cat, we will make the Arduino both read and write registers in the Beckhoff PLC.

TwinCAT 3 can run on a plain-vanilla copy of Windows 7. Also, the license cost scales with the processing power of the PC. On the other hand, industrial PCs are hardened against tougher environmental conditions like dirt and temperature, and they come in nicer form factors for mounting inside of a control panel. They also take a 24V input rather than running from the AC mains. Whatever you do, make sure you invest in a good UPS as well. The performance is phenomenal compared to any other bus on the market today, including any other Ethernet-based technology, and even SERCOS. The price is also quite reasonable because the technology is based on commodity Ethernet hardware.

Twin cat

Industrial automation using PC-based control is insanely fun! The amount of free resources was very limited. Or a combination of all above. This means that the learning curve will be slightly steeper for learning TwinCAT. When creating the content of this course, the ambition was that it should be the course that I wish I had when I started with TwinCAT 3 development. This course has taken me ! Know anyone that wants to learn PLC programming? Please share the course among your friends! The course consists of a total of 18 parts, covering various aspects of TwinCAT 3. If you like the course, please consider supporting making a donation or by becoming a Patron. The first part will be an introduction to why this course was created, the scope and an overview of the content of this course. We will also download and install the TwinCAT 3 development environment XAE so that we have everything up and set for our first program. In this part we will go through some basics regarding why a standard operating system is not suitable for many of the industrial automation tasks, and why you need something like TwinCAT for certain applications.

Click the New Project… link highlighted on the left side of the page.

The TwinCAT 3 engineering components enable the configuration, programming and debugging of applications. The basic components can be extended by TwinCAT 3 functions. The functions are classified into various categories. The TwinCAT 3 runtime components are available for different platform levels. TwinCAT 3. TwinCAT 2 Base consists of runtime systems for the real-time execution of control programs and development environments for programming, configuration and diagnostics.

The cooling activity is controlled in the main program of the PLC project, the signal management take place in another program block. Since no real temperature sensors and no real actuators are connected in this example project, you will also write a program for simulating the rise and fall in temperature. This allows you to monitor the operation of the refrigerator control unit in online mode. You define variables that are to be used by all function blocks in a global variable list. First, declare the variables that you want to use throughout the PLC project. To do this, you create a global variable list:.

Twin cat

Industrial automation using PC-based control is insanely fun! The amount of free resources was very limited. Or a combination of all above. This means that the learning curve will be slightly steeper for learning TwinCAT. When creating the content of this course, the ambition was that it should be the course that I wish I had when I started with TwinCAT 3 development.

Sunset grill bingo

Interfaces provide a layer of abstraction so that you can write code that is ignorant of unnecessary details. Really Appreciated!! After that you will be online with the PLC, and your changes will be applied:. What this does is:. Then we will finish the course by looking at how we can convert between different data types. These variables can be used anywhere in the PLC program. Enter a name for your new virtual PLC in the Name box highlighted above. Submit Quit. In Windows there are only two execution modes: ring 0 and ring 3. Each machine could be controlled by a single virtual PLC, which might be a good way to manage the complexity of a large system. These cookies will be stored in your browser only with your consent. More flexibility in automation development through modularity and extensions.

The TwinCAT 3 engineering components enable the configuration, programming and debugging of applications.

Make a similar video, open the topic. To cut short, how to be sure windows get back all the ressources after a dummy played with twincat? You can see that the motor starter variable coil stayed on. The runtime registers a timer interrupt to force execution of the runtime at a regular interval called the clock tick. The lower grid allows you to configure which tasks run on which core. Your changes will be applied without stopping the PLC program, and without any interruption to the machine. When developing TwinCAT software over time you will most likely end up in a position where you must be able to develop and maintain software for various versions of TwinCAT. You have successfully logged into myBeckhoff. To get feedback of the actuation, sensors are needed. Type the fully-qualified name of the grinding wheel motor starter variable into this field: Grinder. These variables can be used anywhere in the PLC program. The possibility of modular extensions means functional changes and additions can be made at any time.

0 thoughts on “Twin cat”