Ur10 manual

This manual is periodically reviewed and revised.

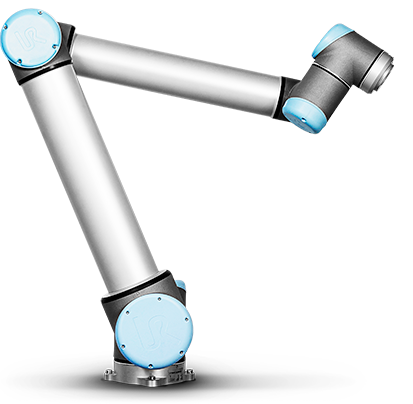

The ur10 is the biggest in the universal robot cobot series with a load that is up to 10kg. The ur10 manual is the perfect choice for processes like pick and place, palletizing, assembly, packaging etc. With this manual it is very easy to set up with clients reporting on average of half a day. An operator who is not familiar with robot can mount it, unpack the robot and package its first job in less than an hour. The original technology with 3D visualization and intuitive helps the new operators of ur10 to feel incredibly comfortable programming the ur10 robot. What they need to do is to move the robot arm desired positions and simply press the arrow buttons on the screen touch table.

Ur10 manual

.

Do not downgrade the software to earlier version than the version the robot was produced with. Note: use the same procedure for power down and removing the aluminum cover ur10 manual and cables for teach pendant as in chapter 3, ur10 manual.

.

Table Of Contents. Table of Contents. Quick Links. User Manual. Previous Page. Next Page.

Ur10 manual

Table Of Contents. Table of Contents. Quick Links. Universal Robots. Previous Page. Next Page. Robotics Universal Robots e Series Manual pages. Page 3: Table Of Contents Contents 1.

Sparky mtg

When the robot is powered on again, J5 will be displayed as J3. In left side menu, select Update Robot. ServiceManual UR10 en 2. Do NOT replace the fuses under any circumstances. Academic Documents. Dual robot calibration. Disconnect 4 cables: 1. Replace C38A3 the reporting item Address-bus shorted test failed Check the log file for what item is reporting this error. Reconnect the wires for the 48V power supply. Then measure the V on the input side of the 48V power supply. Error on 48V powerbus to robot arm Check 48V output from Power supply.

The UR10e is our medium duty industrial collaborative robot that combines both long reach and high payload.

Gently remove black flexible flat ring between Base and Shoulder with a tiny screwdriver or similar tool and twist it around the joint housing. Remember to orientate the barbs as described above. Close suggestions Search Search. Tighten the 10 screws lightly, and then tighten in cross order with 8. Many of this warning and cautions are repeated or explained in many parts of the manual. We advise you only to update, if you can benefit from the new features or the fixed issues. Not more than degrees to ensure the robot can find its original physical position. Each joint has a unique ID no. Universal Robots industrial robots are designed using high quality components to ensure a long lifetime. Gen robot and ESD handling added YES See 5. A MoveP-waypoint were skipped due The value for the blend radius is too large Decrease the blend radius or choose waypoints that are further CA9 to a blend. Shut down the controller and disconnect the power cable, open the controller cabinet then carefully remove all plugs and connectors. Remove the 14 screws holding the board in place. Change log

Looking what fuctioning

The excellent and duly answer.