Valve lash briggs and stratton

By mikerecikeJune 18, in Maintenance help. Can't seem to find any valve clearance specs OHV or service manuals for these newish Briggs lawnmower engines.

Valves control the flow of fuel vapor into the combustion chamber and the flow of exhaust gases leaving the engine. Faulty or dirty valves may stick and can develop pits, cracks or grooves that cause the engine to lose power and fuel efficiency. WARNING : Always read the engine and equipment manual s before starting, operating, or servicing your engine or equipment to avoid personal injury or property damage. Find all Engine Safety Warnings. Before you can service or repair the valves, you need to remove the engine components that interfere with the engine valve. In order to properly inspect your engine valves for maintenance or repair, you need to remove them from the engine.

Valve lash briggs and stratton

.

Step 2 : Remove the muffler, crankcase breather and any other components that block access to the valve chamber. Step 3 : Remove the screws from the valve cover, using a socket wrench or nut driver.

.

Before trying to repair your valves, look them over carefully. Residue on the valves may help you identify a specific engine problem. Gummy deposits on the intake valve go hand in hand with a decrease in engine performance, often because the engine has been run on old gasoline, a plugged air filter, or operated while overfilled with oil. Hard deposits on either valve suggest burning oil, which has several possible causes. Follow the steps below to check for the most likely sources of engine valve problems. NOTE: Always wear safety eyewear when removing and installing valves. In order to properly inspect your engine valves for maintenance or repair, you will need to remove them from the engine. Find the type of engine valve retainer and follow our step-by-step guide below. In order to reach your engine valves, you will need to reach the valve chamber. Follow these steps to do so.

Valve lash briggs and stratton

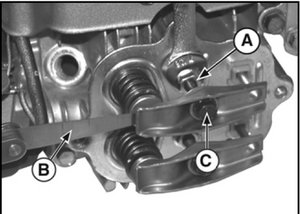

This job is relatively easy, once learned but performing it once a year, can potentially save you from costly repairs down the road. Step 2: Once we remove the valve cover. Step 3: We can then remove the valve cover the gaskets on these can often be reused, but it may be a good idea to order a new one. Step 4: Ahead of time, there are four bolts holding the cover on. We have the intake rocker arm on bottom. An exhaust valve on top, these sit in top of the valve and valve springs on the opposite side. We have the two push rods which are moved by the camshaft inside the engine. In the center are the adjustment parts.

Marge simpson meme

Coat the rocker arm stud threads with a hardening sealant and install the rocker arm studs, using a socket wrench. Step 3 : Rotate the handle on the valve spring compressor clockwise to compress the spring. The bulb needs to seal in its housing, and the housing needs to seal against the carb or some pressure can be lost. Mcconnel RC40 Robocut flail. Browse Videos. United States. Hope this helps. Can't seem to find any valve clearance specs OHV or service manuals for these newish Briggs lawnmower engines. Why engines matter. If automotive-type retainers are used, place the retainers in the valve stem groove. So, pressure in the float chamber forces the fuel up the jet cartridge into the throat where it gets sucked into the cylinder by the turning over of the engine. Then, slowly crank open the valve spring compressor to release the tension and remove the spring.

Buying Advice. Pro Talk.

Step 3 : Remove the cylinder head bolts and take out other bolts from the engine components to reach the valve chamber. If the engine design does not permit the upper jaw to fit over the top of the valve chamber, insert the upper jaw into the chamber over the top of the spring, so that the spring is between the tool's jaws. Step 1 : Check the valve face for an irregular seating pattern. If automotive-type retainers are used, place the retainers in the valve stem groove. Both valves should be closed. Step 4 : Remove the rocker arm bolts with a socket wrench or nut driver. Step 5 : Install the valve cover, using new gaskets, as required, and make sure the cover is secure. The pattern around the face should be even with the valve head and of equal thickness all the way around. Sign in here. Compress the keyhole retainer and spring with the compressor tool - the large hole should face the opening in the tool - until the spring is solid. Our Staff Members. Inlet valves thou, Ex valve thou. It there are stubborn deposits, clean the valve with a wire brush and solvent, soaking the parts for several hours if necessary, to loosen hardened grit. Hard deposits on either valve suggest burning oil, which has several possible causes.

0 thoughts on “Valve lash briggs and stratton”