Welding symbols chart

Next to Welding Certification Welding welding symbols chart are one of the most misunderstood concepts in the welding profession. A lot of welders get by for their entire careers without having a good understanding of welding symbols. The truth is, depending on what kind of job you have, welding symbols chart, you might only have to know a small handful of welding or weld symbols. I once knew a welding supervisor who couldnt read welding symbols.

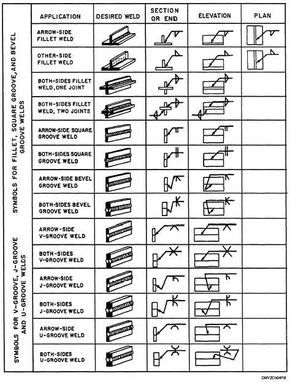

It should be understood that these charts are intended only as shop aids. The only complete and official presentation of the standard welding symbols is in AWS A2. Suitable for framing or displaying on your shop wall, the welding symbol chart is 11 x 17 inches. Click on the image to download the full size chart. With this chart, you can easily convert between fractional, decimal, and metric sizes for all of your shop needs!

Welding symbols chart

This guide will help you to understand different welding blueprint symbols and signs. We will point out the weld callouts with example images and list of options for each aspect of the welding symbol. When designing parts for general metal fabrication, welding symbols, and detailed callouts will be required to communicate design intent and requirements effectively to manufacturers. These callouts will be found on the technical drawings or blueprint of the assembly, also known as a weldment, and will specify weld geometry and its associated size and length requirements. When interpreting a print, the welding symbol will contain all the appropriate information necessary to perform the proper weld on the part. Welding symbols, which are different than weld symbols, contain information such as what weld symbol is being used fillet, bevel, square butt, plug weld, etc. Welding symbols are a menagerie of information, and the combinations of designs and choices that can be made are significant. Example of basic welding symbols. Types of Welding. There exist a variety of welding processes to utilize, but ultimately welding processes are generally agnostic to the process, so long as the symbol callouts are satisfied during the fabrication process. Weld Procedures are generated and used if specific welding processes are required, and these go even further to specify the filler material, any preheat requirements for the part, as well as heat input and feed rates allowed during the welding process.

Below is a comprehensive list of what one can expect to see on a welding symbol, welding symbols chart, as well as an example image and list of options for each aspect of the welding symbol. Functional Functional Always active The technical storage or access is strictly necessary for the legitimate purpose welding symbols chart enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network. Groove Weld Symbols Groove weld symbols specify the groove geometry to be welded, and let the welder know what to expect when preparing to weld the weldment.

.

Chart of Welding Symbols Welding symbols provide a system for communicating complex fabrications requirements from the design stage to the welders executing the work. Published on: 20 July Welding symbols provide a system for communicating complex fabrications requirements from the design stage to the welders executing the work. It provides comprehensive details about the type of weld, its size, its location and other relative information to make a quality weld. A welding symbol consists of several elements to convey specific instructions. Here are the key components:. Understanding the chart of welding symbols involves interpreting these key elements. Here are the main types of welds and their corresponding symbols:. The placement of these symbols on the reference line also indicates where the weld is to be applied relative to the joint. If it appears on the upper side, the weld is to be made on the other side of the joint.

Welding symbols chart

Welding is a complex task with many intricacies, and these intricacies are often communicated in the unique language of welding symbols. One of the first things a new welder must learn is how to read a welding symbol. Without an understanding of how to read a welding symbol or welding symbol chart, it is impossible to understand instructions for even the simplest welds. If you are somebody who is new to welding and would like to improve your understanding of how to read welding symbols, this guide will cover most of the basics for you.

Proxypornhub

When referring to the Basic Weld Symbols chart, note the different potential groove geometries and their visual representation of them. The Root Opening The root opening is a symbol that will be seen on parts requiring a root-pass weld. Please pay it forward. If no length is given, then the weld is to be placed between specified dimension lines if given or between those points where an abrupt change in the weld direction would occur like at the end of the plates in the example above. The flag is important to take note of as the process for welding will change dramatically based on the environment the welding will occur in. Furick-cups Both Clear and Ceramic Furick cups. A Welding Symbol Chart The welding symbol is the whole thing, weld symbol and all. It should be understood that these charts are intended only as shop aids. I once knew a welding supervisor who couldnt read welding symbols. You may also like

T he ability to interpret welding symbols is very important, yet the vast majority of welders have hard time doing so. A very small percentage of companies require that welder candidates know how to read symbols.

Next to Welding Certification Welding symbols are one of the most misunderstood concepts in the welding profession. The welding symbol is the whole thing, weld symbol and all. Furthermore, field weld symbols, denoted by a flag extending from the horizontal line, play a critical role in specifying that a weld should be executed in the field or on-site, as opposed to in a controlled shop environment. This arrow does not always have a straight section, it may be angled to pinpoint the exact location of the weld depending on geometry. Stronghand Tools. The pattern below is also referred to as a stitch weld, and the weld pattern callout is also known as a stitch weld symbol. It will provide information on things like the joint design, the weld pattern, weld size, and many other elements. The Contour The contour is the callout that specifies the actual shape of the weld itself. Conclusion Welding blueprint symbols and signs are of paramount importance in the realm of product design and mechanical engineering, as they provide a standardized visual language that effectively communicates the specifications and requirements for various types of welds and weld joints. Copy and paste it, adding a note of your own, into your blog, a Web page, forums, a blog comment, your Facebook account, or anywhere that someone would find this page valuable. Weld Procedures are generated and used if specific welding processes are required, and these go even further to specify the filler material, any preheat requirements for the part, as well as heat input and feed rates allowed during the welding process. Knowing how to read a welding symbol chart is important and better than trying to memorize them all. A root-pass weld is a weld in which the parts are actually gapped apart with the open space to be a full penetration weld. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site.

I congratulate, your idea is useful