Epson precisioncore vs micro piezo

Think Epson and you probably think consumer printers, epson precisioncore vs micro piezo. Things like high-end presses, large format printers and sophisticated projectors. Clark is well-placed to balance the needs of steering a business making waves with its technological innovations in the inkjet market, whilst built on a strong ecological platform, while charting a course for ambitious growth. A tech savvy business leader, he started his career with the MoD as an electrical and electronic engineer.

While form-factor designs and features come and go, the actual printing equipment — whether laser or inkjet — stays fairly constant. But printer companies are starting to make some noise on the inkjet front. So, what does all that tech jargon mean? Based on piezoelectricity, an electrical charge is applied to the print nozzle to push the ink through versus heat used in thermal inkjet printing to boil the ink. Epson says this tech allows for ink to be dropped more precisely, and it can control the size of the drops. MEMS, in this context, refers to the manufacturing of very small devices.

Epson precisioncore vs micro piezo

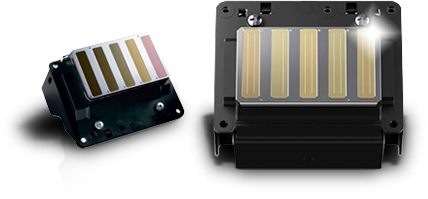

Epson is refining its Micro Piezo inkjet technology and conducting further research and development so that the technology can be used not only in home inkjet printers but also in printer applications for users in the office, commercial, industrial, and other higher-productivity printing segments. Epson's goal is to provide a sustainable printing ecosystem with high environmental performance. Piezo technology deposits microscopic droplets of ink using the mechanical motion of piexoelectric elements. Unique meniscus control technology to constantly eject up to 50, spherical ink droplets per second with high landing accuracy and achieve images of amazing quality at high speed. Nozzles eject ink droplets of various sizes enabling images to be rendered beautifully at high speed. Epson's Micro Piezo printheads automatically sense the condition of nozzles to maintain high print quality. Fabricates piezoelectric elements on silicon wafers by depositing uniform, homogeneous films a mere micron in thickness. Builds mechanical components, sensors, actuators, electronic circuits, and more on a single silicon substrate with sub-micron precision. Advanced type of printhead that reach printing speeds that far exceed those in conventional inkjet printing. Dot control technology makes prints of amazing quality regardless of any type of paper. High-speed paper handling technology achieves both faster and high quality printing. Minimizes the amount of ink stuck to the rollers, prevents ink from being pulled off the paper, and the sheet of paper from being stained. Controls internal mechanisms with high-speed and high-precision for maintaining print quality. Alignment during high-speed printing on inkjet printers has been difficult until now, but Epson's original technology makes it possible.

Information Technology.

When considering what printer to buy, understanding what type of printhead is used can help you to make an informed decision. There are two main types of printhead technology, using either heat or a Piezo element. All Epson printers use a Piezo element as we think it offers the best performance. Having made its global debut in , Micro Piezo technology has not only been at the forefront of Epson inkjet printhead advancement, but has laid down the gauntlet to all the other big names in the print industry. Unique to Epson, Micro Piezo provides superb print quality and is a technology that our competitors still find hard to match. Micro Piezo technology utilises piezo crystals that pulse when electrical signals are sent to them by the printer. It produces incredibly consistent droplets, both in shape and size, to deliver clear and sharp prints.

Epson's inkjet printing technology is used in home, office, and commercial and industrial printers. Since our printing systems form images by directly depositing microscopic droplets of ink on sheets of paper or other media, they generate virtually no waste ink, are far superior to analog and laser printing systems in terms of the environment and efficiency, and can theoretically print on almost any medium. Let's look at the Micro Piezo inkjet technology that powers every Epson inkjet printer. There are two main ways of ejecting ink from a printer. The first is thermal technology, which uses a heater to heat the ink and form bubbles that cause the ink to be ejected. The other is piezo technology, which applies voltage to change the shape of piezoelectric elements, the mechanical motion of which ejects the ink. Micro Piezo printheads are extraordinarily durable because they are not subjected to heat-induced functional deterioration. They are compatible even with inks that would undergo changes of material properties if heated. Printers with piezo technology can use a wide variety of inks, including dye and pigment inks.

Epson precisioncore vs micro piezo

At a press conference at Labelexpo , a premier label industry exhibition, Usui explained how Epson combined years of technical expertise with recent breakthroughs in piezo material and high-precision MEMS micro-electromechanical systems manufacturing to create an innovative new print chip. The new PrecisionCore chip delivers commercial-grade performance in a compact, modular form, and enables Epson to scale the technology from single-pass industrial presses to workgroup and desktop printers. PrecisionCore is the only volume-produced printing technology that spans such a wide range of inks and marking materials. At the same time, scalability allows us to fully leverage our historical strengths of ink flexibility and printhead durability. In conjunction with the PrecisionCore announcement today, Epson is demonstrating several new products incorporating the technology at Labelexpo in Hall 9, Stand 9H50, from Sept.

Fair synonym

Our best-in-class label printing solutions can help improve your overall productivity, no matter what your industry or need. Contact Number: This field is required. Based on piezoelectricity, an electrical charge is applied to the print nozzle to push the ink through versus heat used in thermal inkjet printing to boil the ink. Phillips-Medisize Invests in its Global Manufacturing. We expect Epson will introduce the technology in its higher-end products, eventually rolling it out across its entire lineup. Two characteristics of piezoelectric elements are that they change shape in response to an applied voltage and that as they change shape, they produce a voltage. This field is required. Dot control technology makes prints of amazing quality regardless of any type of paper. Do you have any further requirements? District: This field is required. May 16, Curves come out smooth, small letters stand out in sharp relief, and even gradations and shape fills are rendered beautifully. Get high-quality prints quickly Ink droplets are propelled through each nozzle at 40, times per second to deliver documents at high speeds. Home PrecisionCore.

PrecisionCore is a next-generation inkjet printing technology created by Epson. It achieves excellent image quality even as it greatly boosts print speed. In addition, it significantly expands the range of inks that can be used and materials that can be printed.

Star-Wheel Roller Technology Minimizes the amount of ink stuck to the rollers, prevents ink from being pulled off the paper, and the sheet of paper from being stained. Phillips-Medisize Invests in its Global Manufacturing. Try a JavaScript-free version of this page, if made available by the application author. Interview with Paul Lavoie on Connecticut's Manufacturing. Each Epson ink is specifically designed to provide the kind of durability required for particular applications. Delivering minute detail at incredible speed with unbeatable image quality. Review Form Validation Messages. TFP technology makes it possible to form uniform, homogeneous piezoelectric element films just one micrometer thick on top of a silicon wafer. May 16, Go Back. Explore PrecisionCore. Smart Manufacturing. We will collaborate and engage in open innovation with business partners to use our unique inkjet technology to actively create new markets and provide the world with new value. Things like high-end presses, large format printers and sophisticated projectors. This includes higher speed and more accurate dot placement.

It is remarkable, the helpful information

I can not participate now in discussion - it is very occupied. But I will return - I will necessarily write that I think.

I can speak much on this theme.