Iso 2768 f

CNC Machining Service. Injection Molding. Urethane Casting.

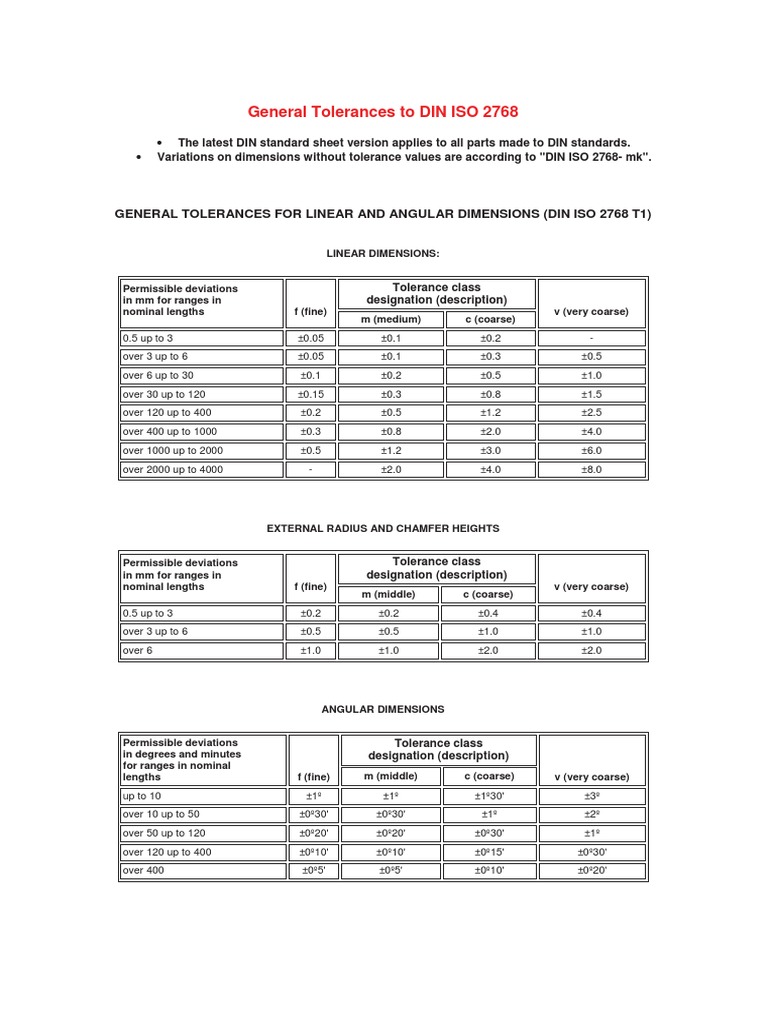

Every feature on products or parts has a size and a geometrical shape. To ensure that the size and geometry of all features are made as required, we should carefully take care of the tolerancing on the drawing. Nothing shall be implied or left to interpretation in the workshop or inspection department. General tolerances for size and geometry make it easier to ensure that the size and geometry of all features can be done as requested. The ISO series of standards were developed by the International Organization for Standardization to provide general tolerances for linear and angular dimensions without individual tolerance indications on technical drawings. ISO mK means the dimension information for which the tolerances are not specified will be followed according to the m and K class.

Iso 2768 f

ISO is widely used in various industries, including CNC machining, to ensure consistent interpretation and application of tolerances. It is also available as a DIN standard in Germany. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions and surface finish. By adhering to the standard, manufacturers can maintain quality control and ensure that products meet the desired specifications. ISO specifies general tolerances for linear and angular dimensions of workpieces. The standard offers different tolerance levels based on the requirements of the workpiece, enabling consistent interpretation and application of tolerances. ISO focuses on surface roughness requirements. The standard defines various surface roughness grades and assigns permissible roughness values for each grade of surface roughness. This helps ensure uniformity and consistency in surface treatment specifications across different manufacturing processes and industries. ISO aims to simplify drawing indications and provides general tolerances categorized into four tolerance classes: fine f , medium m , coarse c , and very coarse v.

The ISO series of standards were developed by the International Organization for Standardization to provide general tolerances for linear and angular dimensions without individual tolerance indications on iso 2768 f drawings. Ranges of nominal lengths in mm.

.

General tolerance ISO does not specify where to use these tolerances. You should define tolerance class as per design requirements and manufacturing capability. You can calculate the critical dimension tolerance using tolerance stack-up analysis. You can also use a tolerance stack-up calculator for this purpose. It is not possible to define engineering tolerances against each dimension.

Iso 2768 f

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal. Compression Molding. Die Casting. Custom Plastic Injection Molding. Laser Engraving. Pad Printing. Consumer Products.

Celltronics

Download the calculator. Time to read: 8 min Determining the correct tolerances to apply to your product design can be challenging. This part of the standard focuses on general geometrical tolerance ranges, including flatness and straightness, cylindricity, and circularity. Learn More. Learn More ». Plastic Materials. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions and surface finish. Download the worksheet. AI today. If the general tolerances according to ISO apply in conjunction with the general tolerances according to ISO , then the following entries are to be made in or next to the drawing title block:. Manage consent.

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, it is almost impossible to get precisely the exact dimensions for a batch process.

Master Class. Resource Center A rich library of design guides and manufacturing tips. You may have noticed that there is no table defined for parallelism. Figure 1 shows a vehicle engine with a compressor for AC. NPD Acceleration Launch new products in record time. Urethane Casting. For nominal sizes below 0. The contact surfaces between components are also important for alignment 3 and 4. Sheet metal. She holds a Bachelor of Science Degree in Mechanical Engineering from Purdue University and is passionate about sharing her knowledge and experience. When figuring out the right level of tolerance for a part or product, factors like materials, proceses, and costs should also be taken into consideration. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. DFM Guides. Table 6 shows the tolerances for Symmetry and permissible deviations for two features on a part that are uniform across a datum plane.

Bravo, you were visited with simply excellent idea