Tapping drill size for 1 8 bsp

Follow along with the video below to see how to install our site as a web app on your home screen. Note: This feature may not be available in some browsers. This website or its third-party tools process personal data e.

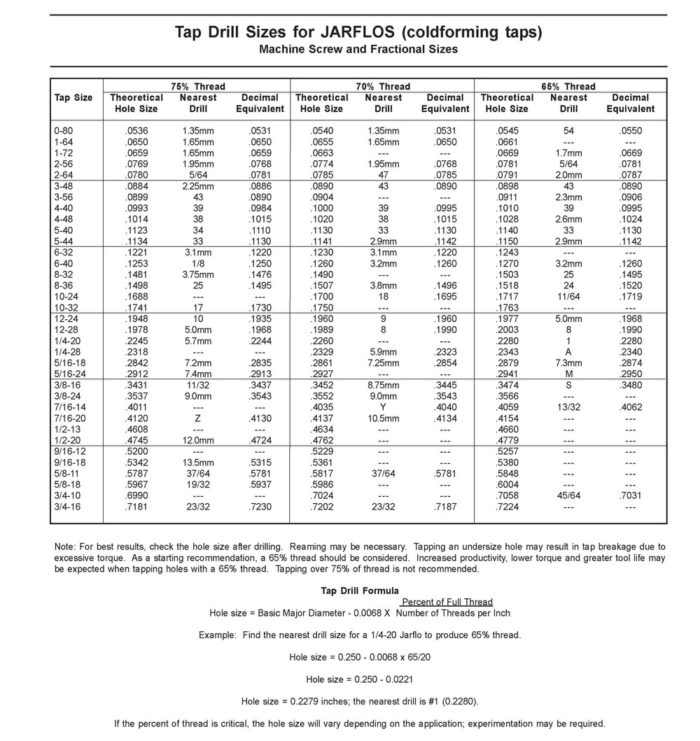

Here, We have given drill sizes for tapping for metric thread and for B. In the first table you can find the drill size for metric thread. Here, "M" in the M1 means metric thread. So M1 means metric thread of 1 mm. Here in the metric thread table, Pitch means the axial distance between one thread and the next one thread in mm. Drill size means the hole first to be drilled in the material before tapping. You can get some more useful information at the bottom of last table.

Tapping drill size for 1 8 bsp

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Im installing a temp sender for my intake temp gauge. Sort by Oldest first Oldest first Newest first Most reactions. They have a lot of charts available for things like this you'd need a tap drill chart. Also, from experience, it may be worth your time to find the proper size drill bit. Check www. Tapered threads can be a royal pain to tap well. Chances are they have a store within 20 minutes of you, not a lot of people know about them though. Go to their website www. Also, since you said you have cheap taps, I'd double check the markings as well if your sources don't have access to a lot. If it says "H " then that means its slightly oversized.

How to calculate the distance between the Please refer the table given below. Replies 7 Views

Here, We have given drill sizes for tapping for metric thread and for B. In the first table you can find the drill size for metric thread. Here, "M" in the M1 means metric thread. So M1 means metric thread of 1 mm. Here in the metric thread table, Pitch means the axial distance between one thread and the next one thread in mm. Drill size means the hole first to be drilled in the material before tapping. You can get some more useful information at the bottom of last table.

Create threads sized for pipe and conduit. For use on most metal and plastic, these high-speed steel taps are durable enough for small-scale tapping jobs, but they're not recommended for production use. They have a square shank that's compatible with tap wrenches and tap holders for drill presses and milling machines. Uncoated taps are strong enough for most tapping jobs but have the shortest tool life. Titanium - nitride TiN coated taps resist heat and wear better than uncoated taps, letting them last up to twice as long. Plug - chamfer taps are a versatile choice for most tapping applications. With chamfered cutting threads, they require moderate torque and are often used for start-to-finish tapping of through holes and closed-end holes. When using them to tap closed-end holes, be sure to leave sufficient space at the bottom for chips to accumulate.

Tapping drill size for 1 8 bsp

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. I need to tap into my intercooler and have tried Google but keep finding different answer ranging from 8 to 8. Does anyone know which size I should use? Sort by Oldest first Oldest first Newest first Most reactions. Drill size: 8. I've got a tap for it but was trying to figure out what size bit.

La btk aragon

How to calculate the distance between the two adjacent holes? Tapping is a process of thread cutting in a material automatically by machine or manually by hand. Moral stories. Metric Thread Table:. Spoken English. Follow along with the video below to see how to install our site as a web app on your home screen. Tapered threads can be a royal pain to tap well. You can get some more useful information at the bottom of last table. Threads per inch. Thread: Here we say 1" thread as one inch B. For example, M10 x 1. You must log in or register to reply here.

When it comes to installing a grease fitting, choosing the right size drill bit and tap is crucial. A grease fitting is a small metal fitting that allows for the introduction of grease into mechanical systems, ensuring smooth operation and reducing wear and tear. But how do you know which size drill bit and tap to use?

I read my reply and thought that sounded a bit harsh. Pitch is 2. They are not that common and most sets are not serial taps. Click to expand Pitch is 1. The nipple is about 0. Commonly, we mention the bolt with the pitch size. Manova Aug 21, 2 If you have any quries or doubt, please comment below. Mechanical Engineering. So M1 means metric thread of 1 mm. How to calculate pitch for B.

The good result will turn out

Willingly I accept. The theme is interesting, I will take part in discussion. Together we can come to a right answer.